Veo Cam 3

Veo Cam 3 - Live-stream camera

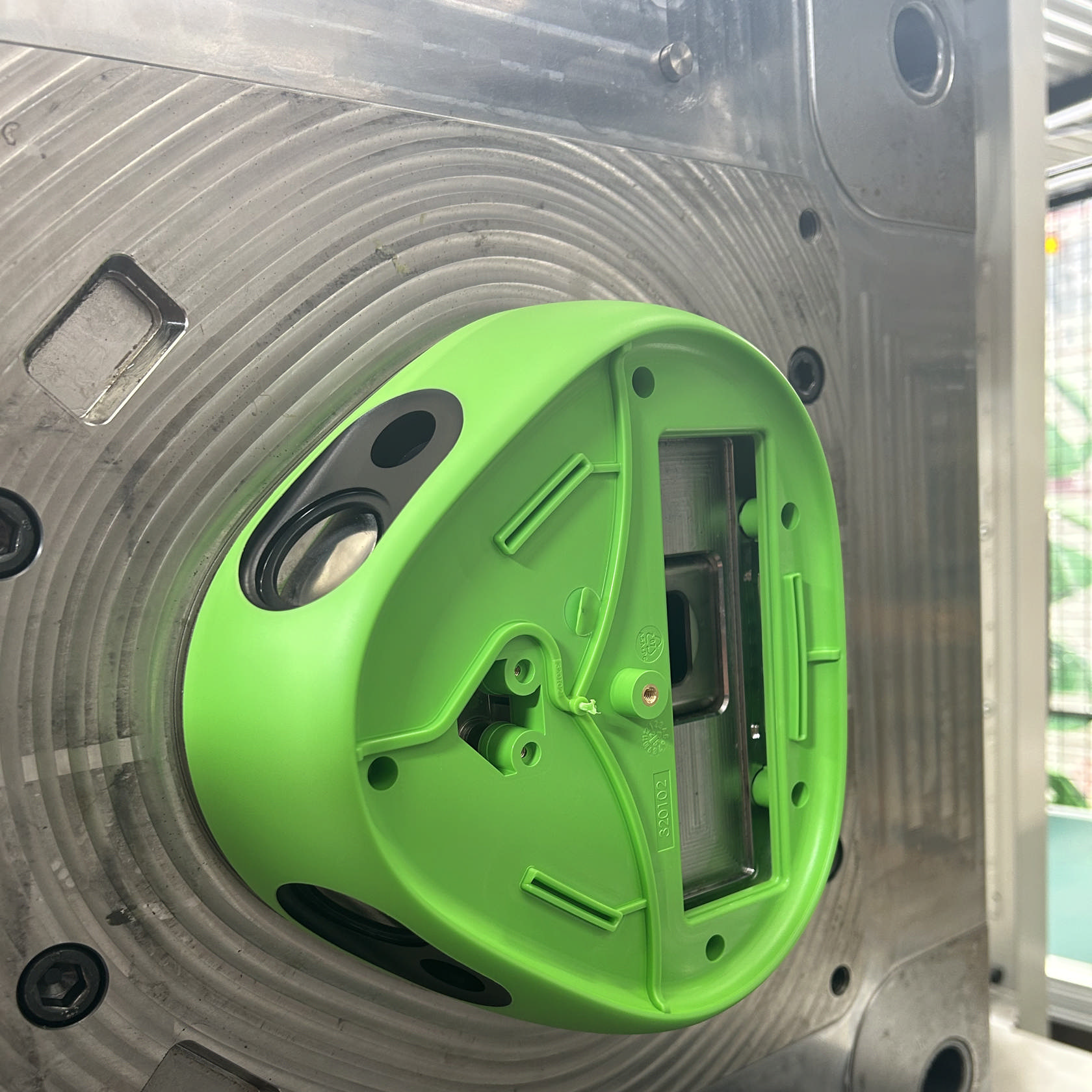

The Veo Cam 3 Sports Camera Launched with Unika as Plastic Supplier

Veo, the company behind the Veo Cam 3, partnered with Unika for the development and production of the plastic components for their newest camera – Veo Cam 3: Best Sports Camera for Recording & Streaming.

Anton Husby, Director of Camera Development, Veo, says:

“We chose Unika as a close partner on this project due to the high complexity of our production processes. We needed a partner with skilled designers who could take responsibility for both moulding and tool manufacturing. By doing so, we avoided the typical finger-pointing between suppliers and instead built a collaboration based on trust and shared goals.”

“We are not only proud of our product, but also of the sustainable approach to its production. Through our collaboration with our plastics moulding supplier, we have helped promote environmentally friendly solutions, including supplying district heating to the local community.” ."

Curious about the Veo Cam 3? Watch the video.

/Default.aspx?ID=8777

Development from Start to Production

The process took seven months and included the following phases:

- Design refinement of Veo’s 3D models, consultation on design, material selection, surface finish, and production readiness

- Design and manufacturing of the injection moulds

- Sourcing of insert components

- Tool try-out and adjustment after first-off parts

- Ongoing production

Both tool manufacturing and injection moulding were carried out at Unika, which enabled a relatively fast process where adjustments could be made within hours instead of weeks. For Veo, avoiding inefficient communication and delays was essential to bring the new camera generation to sports fields around the world as quickly as possible.

From both a design and technical perspective, the Veo Cam project has been demanding, involving many plastic parts and complex moulding techniques.

- Complex moulds with high precision

- 2K moulding on large surfaces

- 2K moulding on both sides of a rigid part

- Varying wall thicknesses in 2K moulding

- Thread insert moulding

- High requirements for part straightness to ensure sealing performance in 2K-moulded gaskets and ease of assembly:

- Advanced simulations of strength and deformation in collaboration with the customer

- Flow analysis using Moldflow

- High number of angled ejectors and moulds with slide mechanisms

- Development of a new TPE material specifically for this project in collaboration with the material supplier. The material:

- Provides a pleasant, high-quality surface feel when handling the camera

- Is scratch-resistant and functions as a seal between components, ensuring the camera is waterproof and that screws do not loosen over time

Thank you to Veo for a great collaboration, and congratulations on your new camera.

Let us help you move forward

At Unika, technology is not just about machines – it’s about applying precision and efficiency to supply machine and tool components, injection moulds, and plastic parts of the highest quality.

Involve us early in the process to achieve the best result.

We are ready to provide expert guidance and a non-binding quote. We support you in the areas where you need additional expertise to reach your goals.