Injection Moulding Tools Manufactured in Denmark

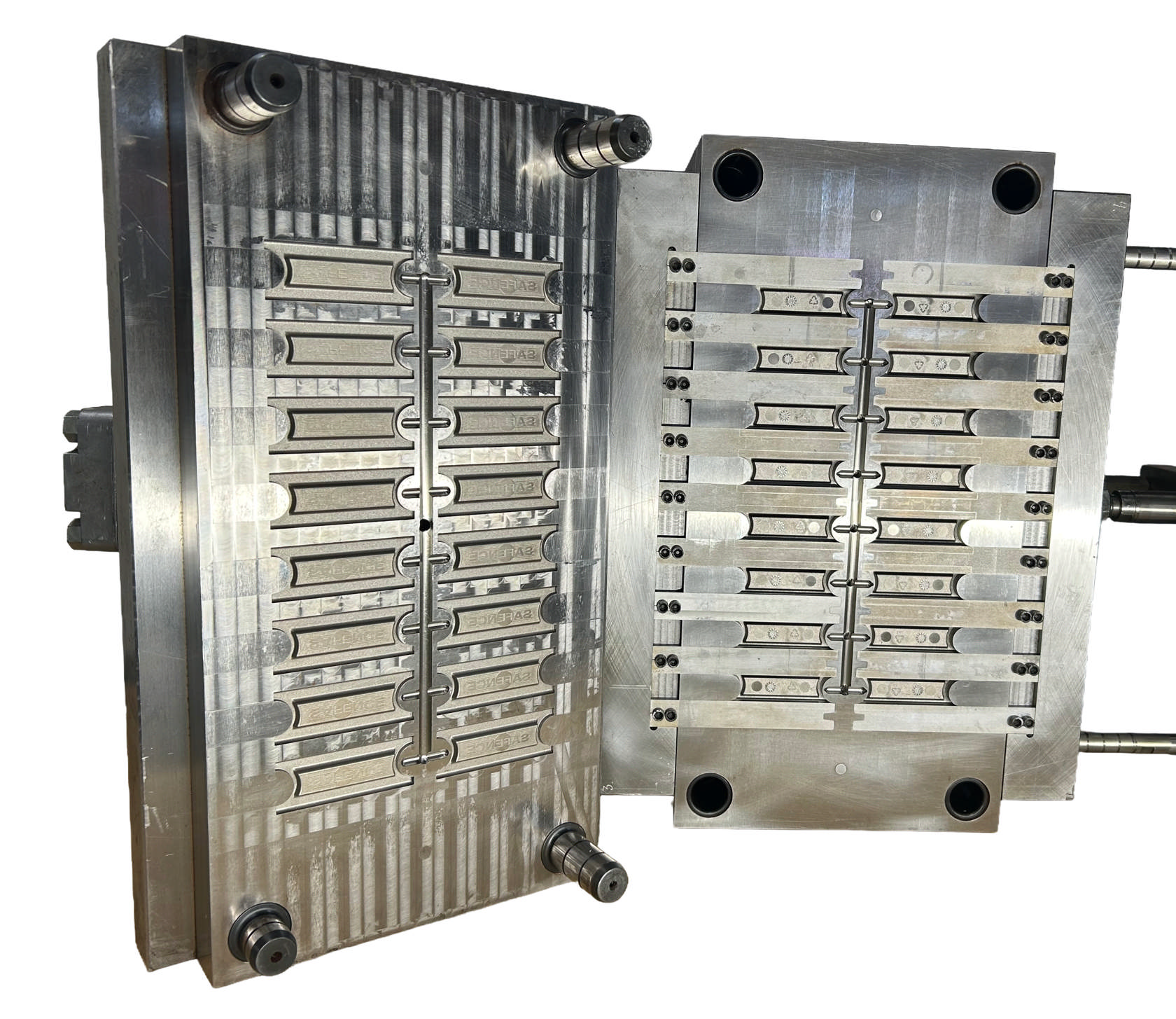

UNIKA’s In-House Injection Moulding Tools

At Unika, we have over 50 years of experience manufacturing injection moulding tools at our own facility. When it comes to complex components or when proximity is important for other reasons, many customers choose to have their injection moulding tools designed and produced by us.

We design, manufacture, and test injection moulding tools at our own facility in Denmark. Our specialists and experienced workshop team ensure that we can successfully handle every project.

We produce various types of injection moulding tools for multiple industries:

- Multi-cavity, high-volume production with short cycle times

- Tight tolerances, complex geometries, overmoulding, 2K moulding, etc.

- Long service life and easy maintenance

- High-quality surfaces, precise component details, and material-optimized designs

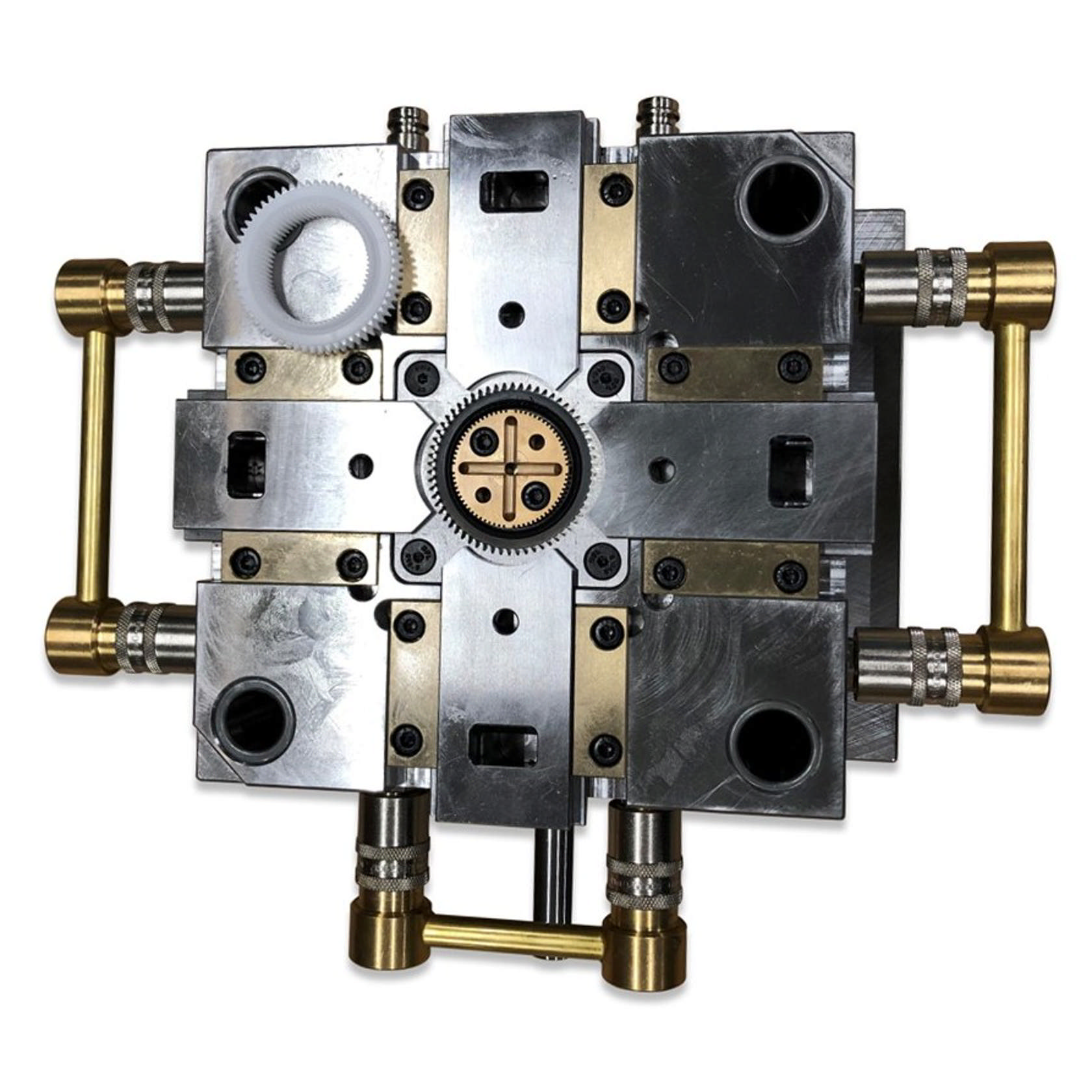

Injection Moulding Tools Using Various Techniques

- **Collapsible cores**

- **Threaded Cores**

- **Banana/rotating cores**

- **Side-action tools**

- Overmoulding

- 2K moulding

- Insert moulding

For components with lower volumes

If the component is to be produced at Unika, we offer several flexible options that reduce the investment in the injection moulding tool:

- Master moulds, where only single insert is required, reducing the investment

- Family moulds, where multiple components are combined in the same tool

- Aluminum inserts, which makes the process faster and more cost-effective

We have the expertise and equipment for the job:

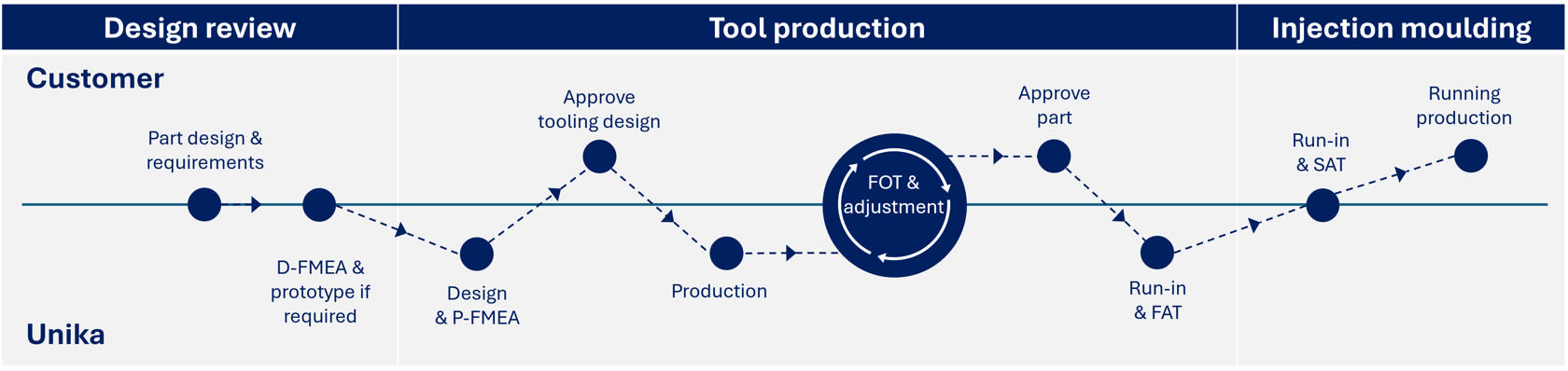

The Development PRocess

We guide you every step of the way, from concept to a production-ready injection moulding tool

The process is a collaboration, with us serving as your injection moulding experts. If you provide a designed component, we perform a design review regarding injection moulding. If you provide only a sketch, we can assist with the entire design process.

An experienced team is assigned to each project:

- Project manager

- Part and tool designer

- PTA/PTQ responsible for production technology and quality

- Operator for start-up and commissioning of the injection moulding machine

We follow a structured process that ensures the fast and efficient completion of your project, with the necessary alignment of requirements along the way.

Explanation of Abbreviations

- D-FMEA - Design Failure Modes and Effects Analysis

- P-FMEA - Process Failure Modes and Effects Analysis

- FOT - First Out of Tool

- FAT - Factory Acceptance (Test performed at Unika)

- SAT - Site Acceptance (Test performed at your site)

Component and tool documentation is prepared to support efficient start-up and validation in ongoing production. This can include complete PPAP documentation or selected elements, depending on the requirements for the component and injection moulding tool.

Whether you need a single tool or an entire tool range, we deliver the solution – on time and of the required quality.