Metalworking

Metalworking

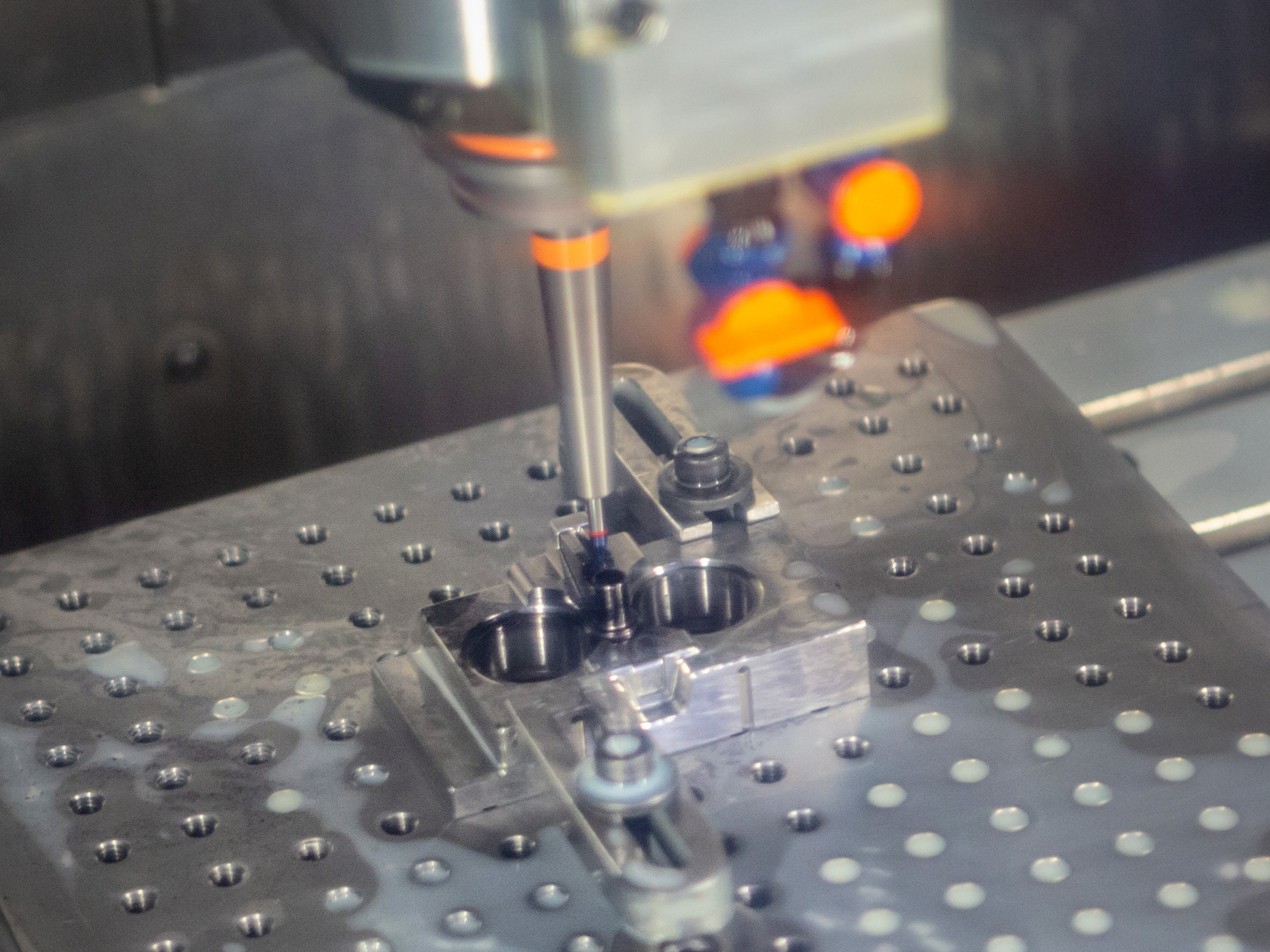

Well-equipped machine workshop for precision components.

Unika’s tooling department is among the most experienced and well-equipped in Denmark. We specialise in the development, manufacturing, and maintenance of a wide range of tools and components:

- Injection molding tools for the plastics industry

- Cutting & punching tools and tooling components for roll forming and other metal forming processes

- Machine components and spare parts designed to fit production equipment

Unika’s tooling department has advanced machining centres for milling and turning, EDM, grinding, and precision measurement technology, ensuring accuracy and reliability.

Over the years, we have developed extensive knowledge of material properties and surface treatments, which enhances the service life of the components we produce. By combining this expertise with our machining capabilities, we can make a significant difference for our customers’ tools and machinery.

With our high technical capacity and rapid response times, Unika ranks among the top Danish suppliers of tooling and is a trusted partner for complex and critical projects.

Milling

Our nine 5-axis machines handle complex geometries in a single setup, reducing errors and increasing accuracy:

- Hermle and DMG Mori – renowned for stability

- Makino – precision machining at high speed

- Röders – high-speed milling with very fine, tool-grade surface finishes

Röders Special Machines

- CNC high-speed milling (Röders RXU 1001 DSH & RXP 501 DS)

- Built for hard and hardened materials.Can achieve finer surface finishes than traditional milling.

- Used for mold inserts, precision contours, and fine surfaces.

- RHP500 with Pallet System, used for geometries where surface quality and dimensional accuracy are critically important.

- Widely used in tool manufacturing, where both geometry and finish are essential.

Turning

Roundness Accuracy and Multi-Operation Capability:

- Hembrug Microturn: An ultra-precise precision lathe ideal for tight tolerances and smooth surfaces.

- Mazak and Okuma multitasking machines: Capable of both turning and milling, perfect for parts where multiple processes are combined in a single setup.

We produce shafts, inserts, and rotating components with high complexity.

Spark Erosion

For challenging part designs and features that cannot be milled:

EDM (Electrical Discharge Machining) centres are used for very small cavities, sharp corners, and complex contours, including in hardened steel.

- Wire EDM: Cuts fine contours with high accuracy. Ideal for cutting tools and cores with very tight tolerances.

- Sinker EDM: Shapes internal geometries that cannot be machined using conventional methods.

We have seven EDM centres suitable for both small, intricate details and larger electrode surfaces.

Grinding and Polishing – Premium Finish

- Cylindrical Grinders – for components requiring high cylindrical accuracy

- Surface Grinders – for creating precise flat surfaces

- Universal and Tool Grinders – for grinding complex tool parts and mold geometries

- Manual and Robotic Polishing – leveraging expertise, polishing compounds, and equipment options

Supplementary Technology

- Reverse engineering when CAD data is missing

- Stratasys 3D printer for rapid prototyping and fixtures in ABS

- Laser engraving and welding for marking, repair, and assembly

- Micro-blasting systems for cleaning small mold details and post-EDM cleaning

- Industrial ovens for hardening and stabilization

- 3D printing of mold components in metal to achieve improved cooling channels