QUaLITY

Quality every day

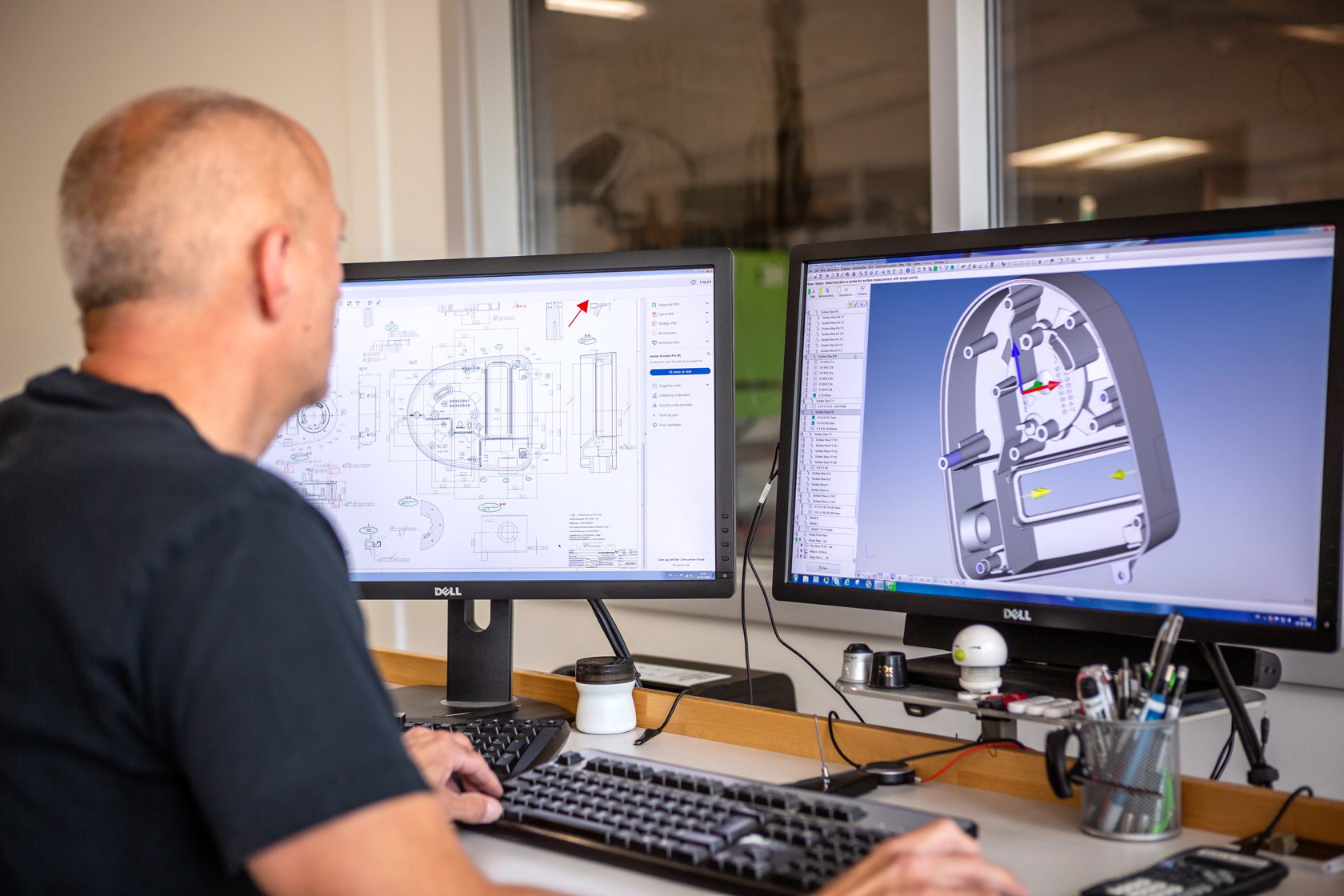

An integrated part of our culture

At Unika, quality is an integrated part of both our culture and our product. Our customers operate in industries with strict requirements for precision, documentation, and traceability. We meet these demands through systematic work processes, technical expertise, and advanced measuring equipment.

Our quality is backed by:

- ISO 9001-certified quality management

- UL and FKM certifications

- Measuring facilities equipped with advanced inspection technology

- Quality assurance through measurement, documentation, and compliance control

We ensure that quality is maintained throughout the entire process – from design and engineering to delivery of the final product, including all required documentation.

ISO 9001 – A QUALity Guarentee

At Unika, quality is not just a goal; it is the foundation of everything we do and is embedded in our entire business, from project start to the final product.

ISO 9001 is your assurance that we work systematically and purposefully with quality throughout the entire value chain – from the first customer dialogue to the finished product and documented inspection. This includes:

- Clear processes and procedures

- Continuous improvement based on facts and data

- Customer satisfaction as a key focus

- High traceability and documentation

- Efficient handling of deviations and risks

We are accustomed to working with strict requirements and standards and use UL-approved plastic materials.

We supply injection-moulded plastic components in materials with UL 94 certification (e.g. V-0, HB) and ensure documentation and traceability in accordance with UL requirements.

FKM-Certification

Unika manufactures metal components and plastic products intended for contact with food and complies with EU Regulation (EC) No 1935/2004

As we handle materials and articles intended for food contact, we are registered with the Danish Veterinary and Food Administration in accordance with Food Order No. 681 and section 15 of the regulation.

We provide Declarations of Compliance in accordance with applicable EU legislation for the materials in our production that are suitable for food contact.

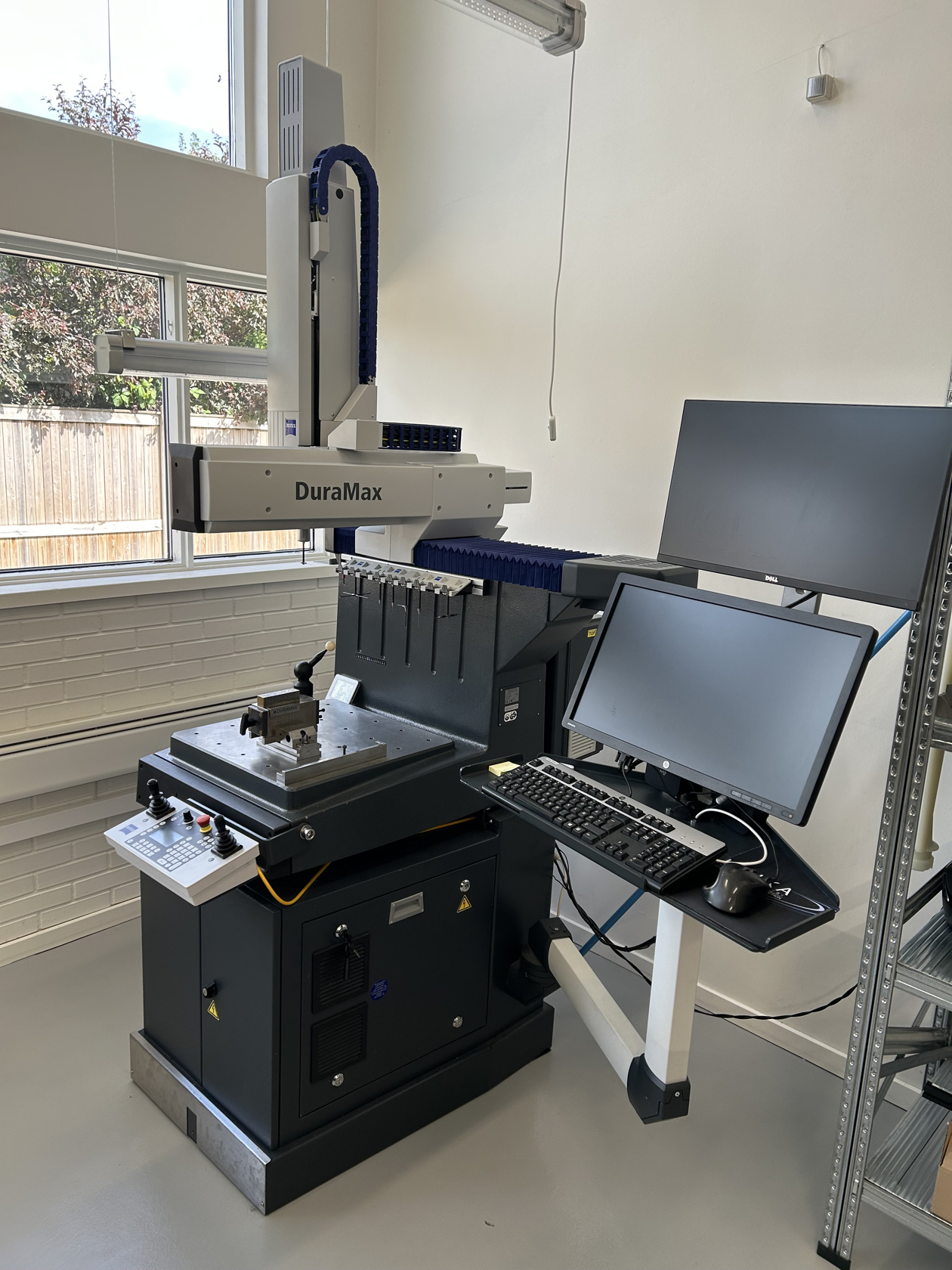

Measuring room

Documented Precision

We work with total tolerances down to 0.005 mm, and inspect components and tooling using some of the most accurate coordinate measuring machines (CMM) on the market.

Quality Assurance

Measurements and documentation to ensure compliance with requirements

At Unika, we provide comprehensive documentation and quality assurance for the manufacturing of metal and tooling components, the injection moulding tool itself, as well as during plastic part production.

Quality assurance and the related documentation are tailored to match each customer’s requirements and expectations. Parts and components are validated and documented according to the necessary tolerance specifications and inspection level.

For example, we can offer:

Plastic COmponents:

- Part drawings with reference to inspection points

- Full or partial PPAP – documentation package for validation of part and process stability before serial production, including:

- GR&R / Measurement System Analysis

- Measurement Report for parts

- Process capability (Ppk / Cpk)

- Color mapping – visual comparison of part to 3D model

- SPC – Statistical Quality Control during production

- Raw material certificates (CoC, CoA, DoC)

Injection Moulds

General:

- D-FMEA (Design Failure Mode and Effects Analysis)

- 2D and 3D drawings

- Measurement report for critical parts

For moulds transferred to the customer:

- Start-up/setting instructions and process data

- Maintenance instructions

- Spare parts list

- FAT / SAT with corresponding documentation to support potential later IQ/OQ validation

Metal and tooling PArts:

- Reverse engineering when CAD data is unavailable

- Measurement reports

- Color mapping for visual comparison of parts and 3D model

- Metrology support throughout the entire process

Let us help you move forward

At Unika, technology is not just about machines – it’s about applying precision and efficiency to supply machine and tool components, injection moulds, and plastic parts of the highest quality.

Involve us early in the process to achieve the best result.

We are ready to provide expert guidance and a non-binding quote. We support you in the areas where you need additional expertise to reach your goals.