Injection Moulding

Injection Moulding

From Idea to Plastic Product

At Unika, we have specialised in the development and production of technical plastic components for over 50 years.

We handle the entire process under one roof, from:

- Concept, part design, and prototyping

- Production or sourcing of injection moulding tools

- Injection moulding of the finished part

This provides our customers with maximum flexibility, high quality, and short delivery times.

We are often chosen as a collaboration partner due to our many specialists and our work with several major, well-known Danish companies.

We are ISO 9001 certified, continuously meet documentation requirements at PPAP level, and are regularly audited by our customers.

/Default.aspx?ID=8777

We have the experience to find YOU the right solution

At Unika, we design and mould a wide range of parts using various injection moulding techniques. We produce technical plastic components for multiple industries and applications:

- Housing solutions with IP requirements

- Electronics and cable encapsulation

- Pump and motor solutions

- Ventilation and extraction systems

- Micro components for the optics industry

- Robots and drones

- Food handling and food equipment manufacturers

- Furniture industry

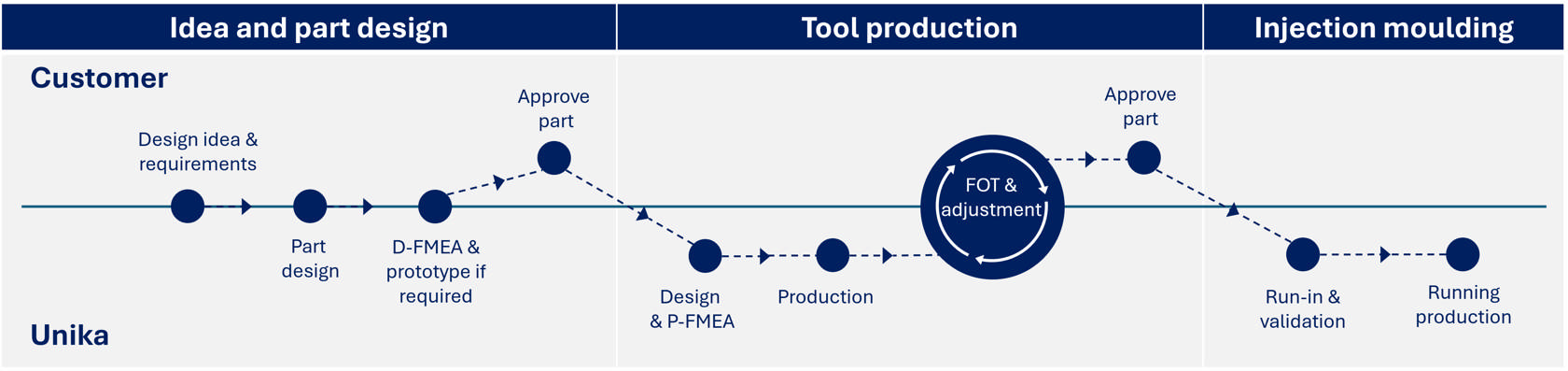

The development process

The development process is a collaboration in which we act as your injection moulding experts. Each project is assigned an experienced team consisting of:

- Project manager

- Part and tool designer

- PTA/PTQ responsible for production technology and quality

- Operator for start-up and commissioning of the injection moulding machine

We follow a structured process that ensures the fast and efficient completion of your project, with the necessary alignment of requirements along the way.

The Three Steps from Concept to Finished Product

Explanation of Abbreviations

- D-FMEA - Design Failure Modes and Effects Analysis

- P-FMEA - Process Failure Modes and Effects Analysis

- FOT - First Out of Tool

Let us help you move forward

At Unika, technology is not just about machines – it’s about applying precision and efficiency to supply machine and tool components, injection moulds, and plastic parts of the highest quality.

Involve us early in the process to achieve the best result.

We are ready to provide expert guidance and a non-binding quote. We support you in the areas where you need additional expertise to reach your goals.