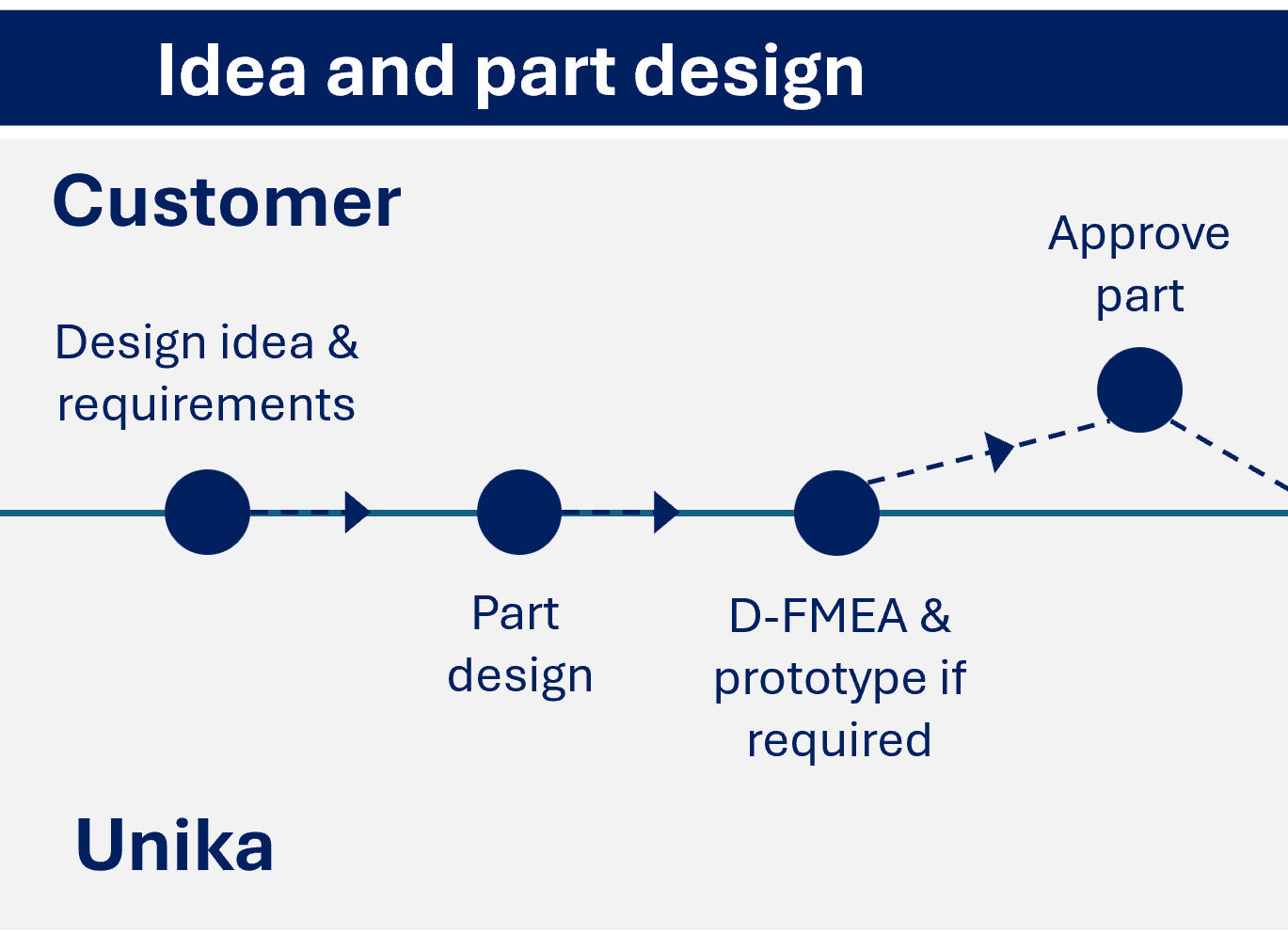

IDea and part design

IDea and part design

A good plastic solution starts with a strong design

At Unika, you work closely with our development team to transform your requirements and ideas into a finished 3D design, ready for production. We develop from sketches, drawings, or a simple concept and provide guidance throughout the process to ensure you achieve the best solution in terms of form, function, and cost.

When designing plastic components, we always start with a thorough specification of requirements. This includes all relevant parameters such as UV resistance, chemical resistance, temperature effects, electrical properties (e.g. UL approvals), and the mechanical requirements the component must meet.

The material type is selected based on the component’s requirements. We advise and guide you on material selection and work with a wide range of plastic types.

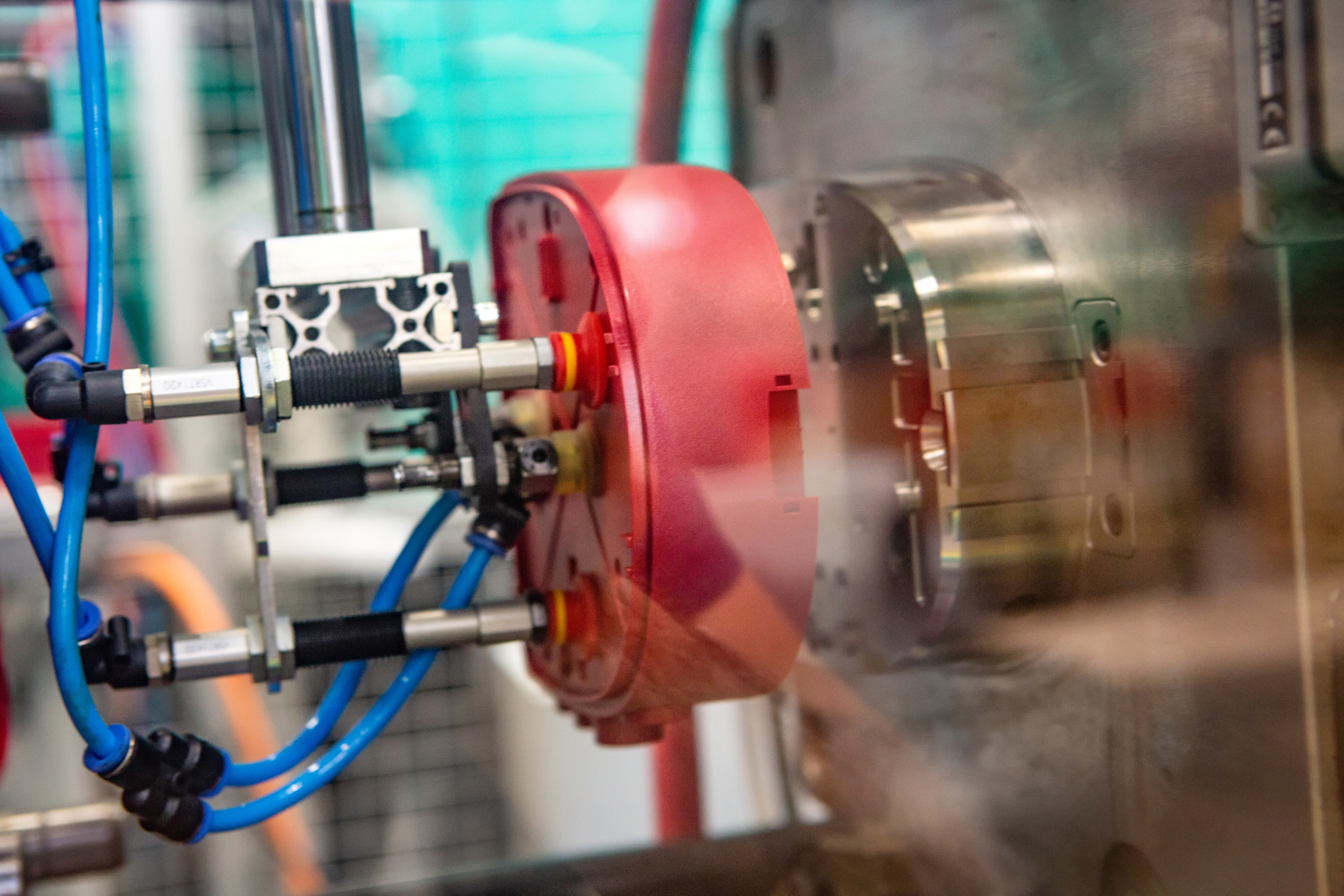

Injection moulding techniques with a wide range of options

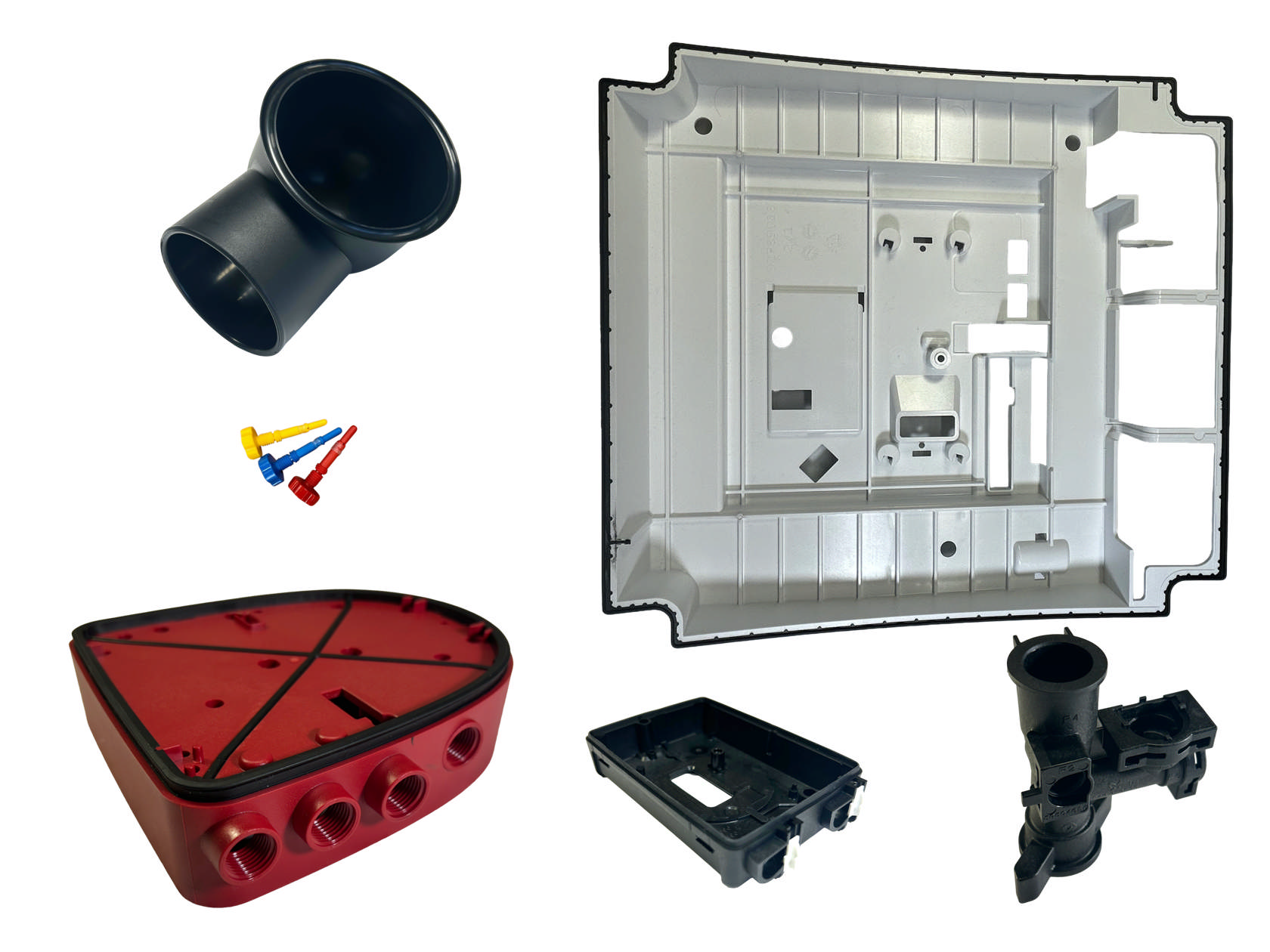

At Unika, we design and mould a wide variety of components using several different injection moulding techniques.

- 0.1-gram components with tight tolerances

- Up to 12-kilogram components - large robust parts

- 1K and 2K moulding – including insert moulding of various metal and brass parts such as bushings, and overmoulding with sealing material.

- Encapsulation of electronics and cables

- Components with unscrewing threads

- Vertical moulding for encapsulation of non-magnetic parts

- Compression moulding

We transform your ideas into fully developed solutions

Full control of requirements and production

For example, we offer design workshops where we provide guidance on part design and collaborate with the customer’s designers. We follow the principles of Design for Manufacturing and Assembly (DFMA), designing for simple, cost-effective production and assembly. This minimises waste, simplifies tooling, and ensures the best solution.

Using advanced simulation software, we identify potential challenges in the moulding process early and adjust the design accordingly.

Prototypes

Test your ideas quickly and reduce development time with a prototype

A prototype allows you to test and evaluate functionality, fit, and design before investing in a final, often expensive, injection moulding tool. This minimises the risk of errors and ensures that the finished component meets all requirements. The prototype can also be used for presentations, market testing, or as documentation in approval processes.

Depending on the needs in the development process, we work with:

- 3D-printed prototype components to test functionality

- Milled and turned prototype components when higher-quality prototypes are required to test functionality

- Material test moulding if surface finish and shrinkage properties are critical to meeting component tolerances

- Moulded prototype components in a prototype tool if mechanical properties need to be evaluated. These tools can, in some cases, also be used for production start-up

Tool production is the next step

Once the part design is finalised and approved, we prepare to manufacture the injection moulding tool.