tool Production

Tool production – the next step in the process

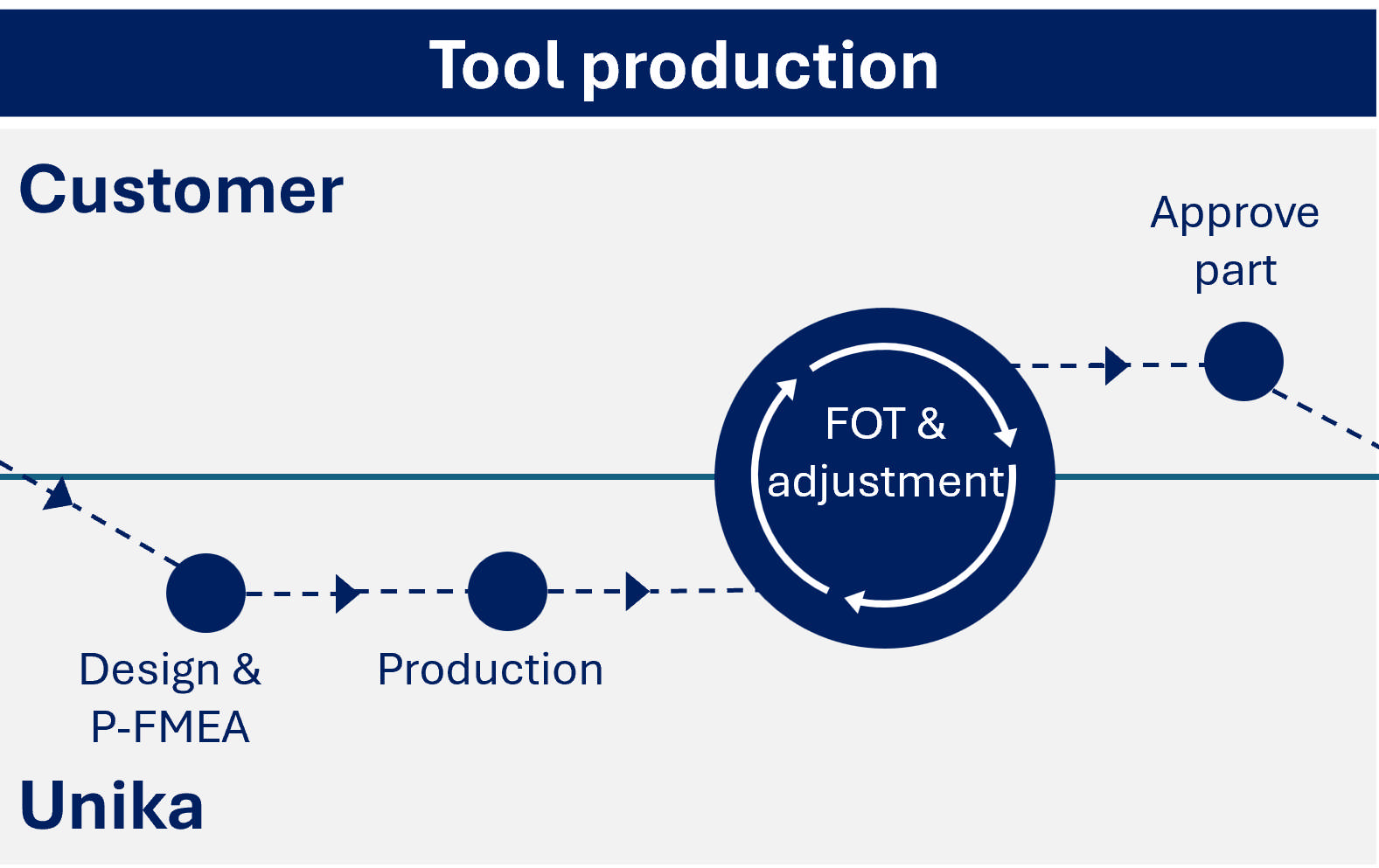

Once your idea is finalised and your component is fully developed, Unika guides you through the next stage of the process: manufacturing the injection moulding tool itself. Based on the approved component and any prototype, we design and produce the tool. You, as the customer, are involved throughout the entire process.

At Unika, we have specialised in the development and manufacturing of injection moulding tools, with a focus on functionality, durability, and cost-efficiency. We deliver precise and reliable tools that are tailored to your needs.

Our structured and flexible approach ensures that you receive the right solution for your requirements and budget. Everything is handled under one roof, guaranteeing maximum quality and delivery reliability.

Depending on the budget, schedule, and complexity of your product, you can choose to have the tool manufactured in-house at Unika in Denmark or by a low-cost manufacturer abroad.

tools manufactured at unika

When dealing with complex components or when proximity is important, we recommend having the tool manufactured in-house at Unika.

When we manufacture tools in-house at Unika, we guarantee precision from the very beginning. Tool design, FOT, and validation are carried out in close collaboration with you.

When we develop moulding tools, we start with a thorough tool design, considering the component’s function, material selection, and production requirements from the outset. Once the moulding tool is ready, we produce the first component – also known as First Out of Tool (FOT).

For FOT, we invite you to Unika, where we review the first moulded component together. Here, we collaboratively validate geometry, functionality, and quality, agreeing on any necessary adjustments before the production run begins. This ensures that you achieve the correct result.

Bringing tools in from abroad

Unika is responsible for quality assurance

There is money to be saved by having tools manufactured abroad. We collaborate with selected tool suppliers in Europe and Asia. This allows us to offer sourcing and project management of tools for customers who want a competitive price without compromising on quality.

We handle:

- Technical specifications and design review

- Close quality control and inspection

- Inspection, testing, and fine-tuning in Denmark

- Support and maintenance after delivery

With Unika as the link, you gain confidence and technical insight throughout the entire project – even when the tool is manufactured outside of Denmark.

Injection Moulding is the next step

Once the tool is ready and the first component is approved, we prepare for injection moulding.