Injection Moulding Tools

Injection Moulding TOols

At Unika, we specialise in developing and manufacturing injection moulding tools, with a focus on performance, durability, and cost-effectiveness.

We offer:

- Tools manufactured in-house in Denmark

- Import of tools manufactured by a low-cost overseas supplier

- Repair and maintenance of injection moulding tools

We are happy to advise you on selecting the right tooling solution. Choosing a tool manufactured overseas typically offers a lower cost but is often more time-consuming. When an injection moulding tool is produced in-house at Unika, you stay closely involved throughout the entire process.

In all cases, our structured and flexible approach ensures you get the right solution for your needs and budget. Everything is handled under one roof – for maximum quality and delivery reliability.

Learn more about what we offer and how we work.

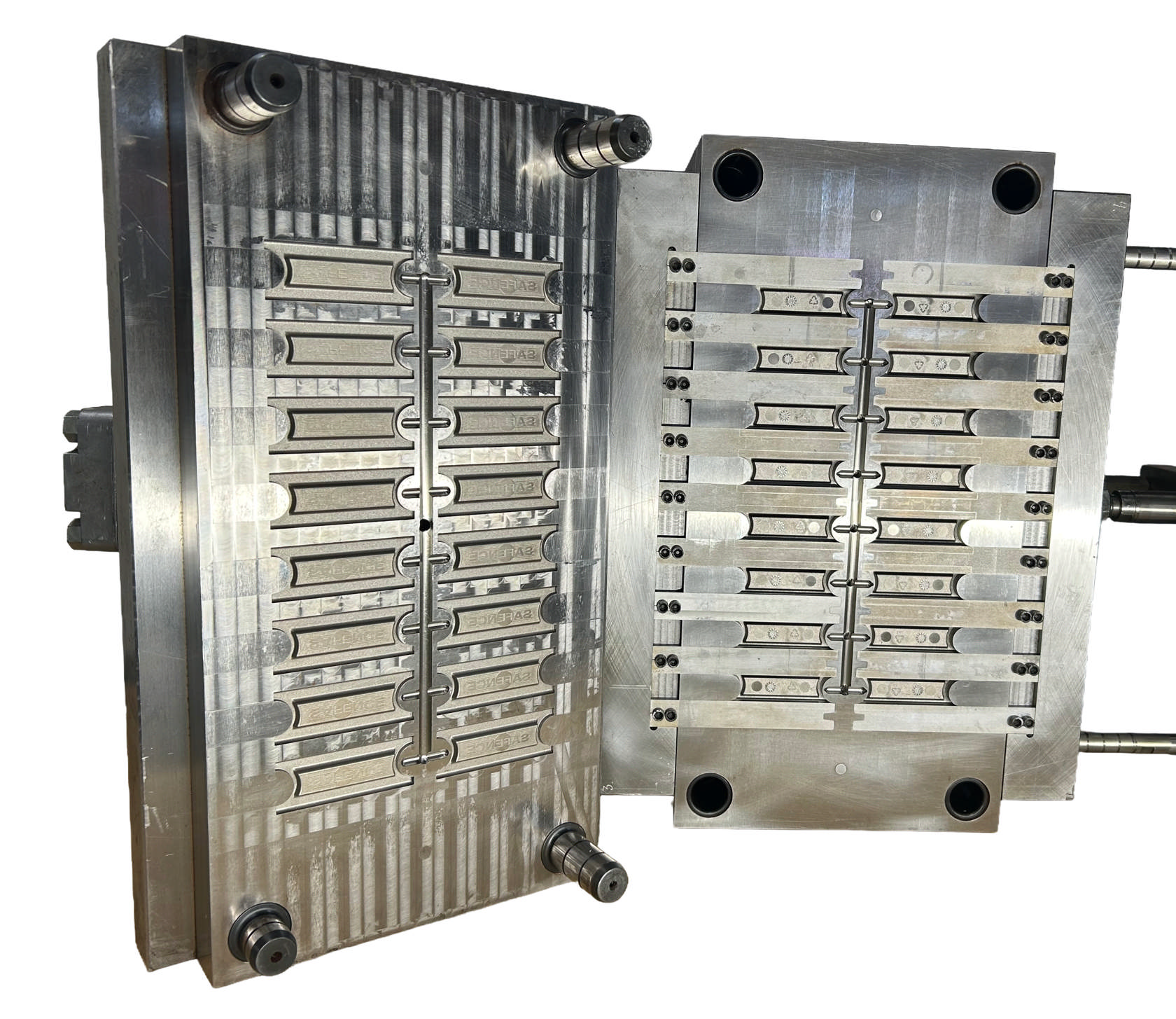

What is an injection moulding tool?

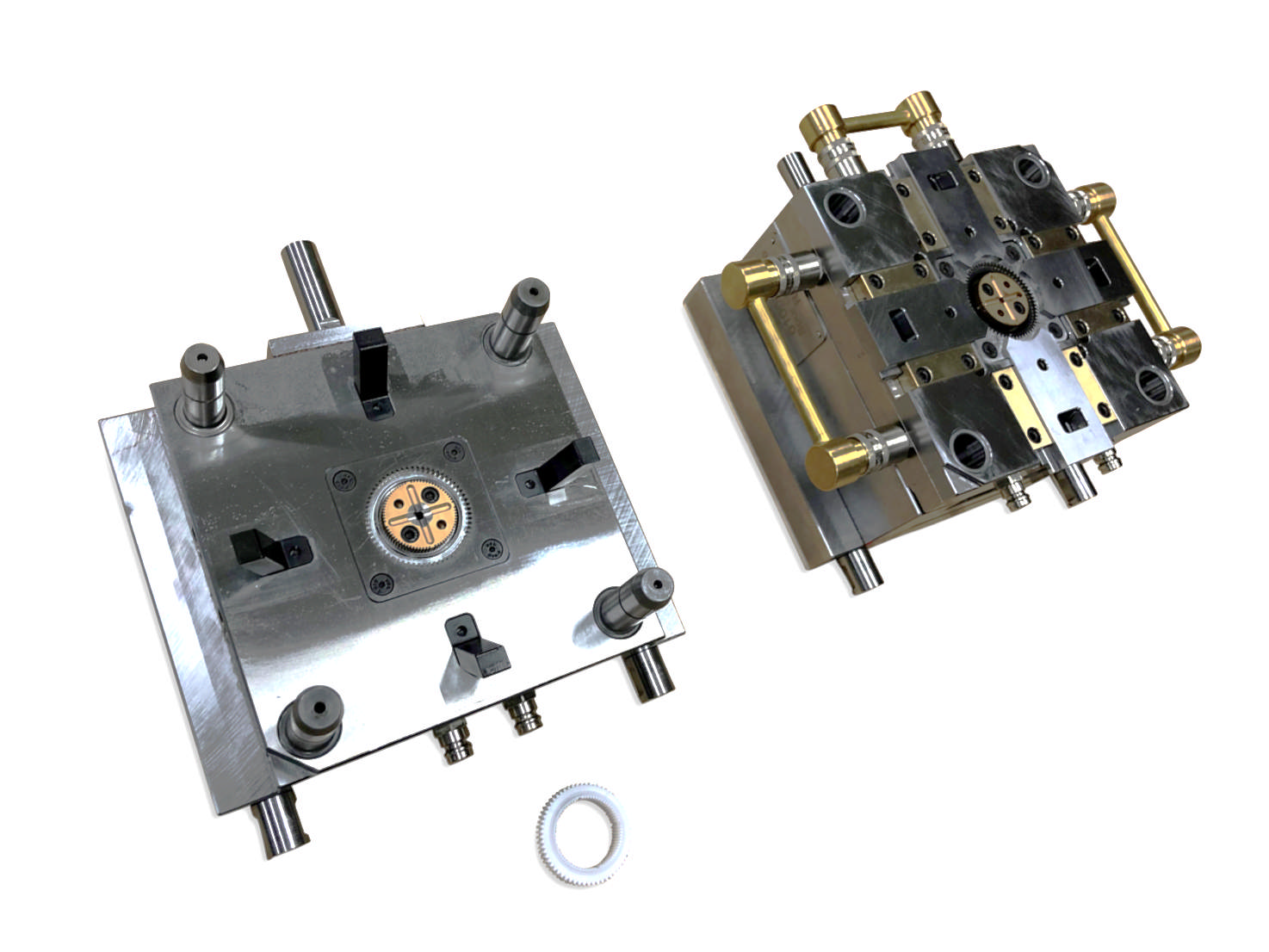

An injection moulding tool is a precision-engineered mould used in the injection moulding process to produce plastic components. The tool typically consists of two main parts – a mould half (nozzle half) and a counter-mould (ejector half) – which together form a closed cavity where the heated plastic material is injected under high pressure.

Once the plastic has cooled and solidified in the cavity, the tool opens, and the component is automatically ejected using an ejector system. The design and construction of the tool depend on the component’s geometry, tolerances, material, and the desired production volume.

A standard injection moulding tool typically consists of the following components:

- Mould plates and inserts, which form the cavity and, if applicable, the cores

- Cooling systems (channels for water or oil) that ensure efficient temperature control and short cycle times

- Injection system (runner system and gate), which leads the plastic from the injection unit into the cavity.

- Ejector system, which removes the finished component without deformation.

- Guide elements and sliding systems, which ensure precise opening and closing

Tools can be designed with one or more cavity units (multi-cavity tools) to increase capacity. Complex tools may also include moving cores, sliders, and inserts to enable undercuts or advanced geometries.

The development of an injection moulding tool requires careful coordination between design, material selection, machining, and testing. It is a critical investment in any injection moulding production, where high demands are placed on precision, cycle time, and operational reliability.

Let us help you move forward

At Unika, technology is not just about machines – it’s about applying precision and efficiency to supply machine and tool components, injection moulds, and plastic parts of the highest quality.

Involve us early in the process to achieve the best result.

We are ready to provide expert guidance and a non-binding quote. We support you in the areas where you need additional expertise to reach your goals.