Cutting, Punching, and other tool components

TOol cOmponents from unika

In many production environments, tool components are exposed to extreme stress – repeated movements, high pressures, temperature fluctuations, and wear from hard materials. When tool components cannot withstand daily operations, it often results in breakdowns, reduced quality, and higher maintenance costs.

Durable tool components are not just an advantage – they are a necessity.

By choosing durable tool components, you ensure a more reliable and efficient production process that can handle daily challenges – even in demanding environments.

We manufacture tool components for a wide range of tool types:

- Cutting and punching tools

- Injection moulding tools

- Die-casting tools

- Vacuum forming tools

- Deep-drawing and drawing tools

- Roll tools

- Cold-flow pressing tools

- Bending tools

Benefits of durable tool components:

- Longer service life: Durable parts minimize frequent replacements, saving both time and money.

- Stable production: Reduced risk of downtime and production errors.

- High precision: Durable tools maintain their shape and function over time, ensuring consistent quality.

- Lower total costs: Investing in durable components quickly pays off through reduced repairs and increased efficiency.

We have the experience to manufacture your tool components.

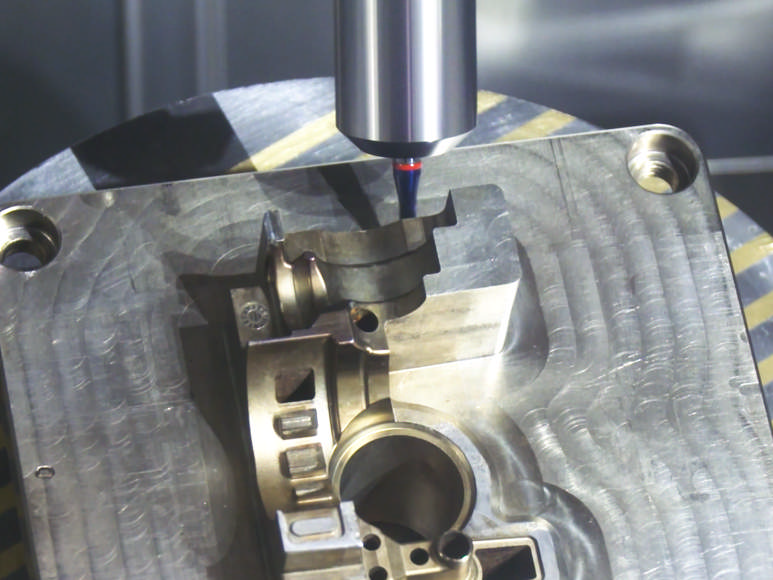

Manufacturing complex tool components with tight tolerances requires experience. At Unika, we have that expertise, with skilled industrial technicians producing advanced machine and tool parts every day.

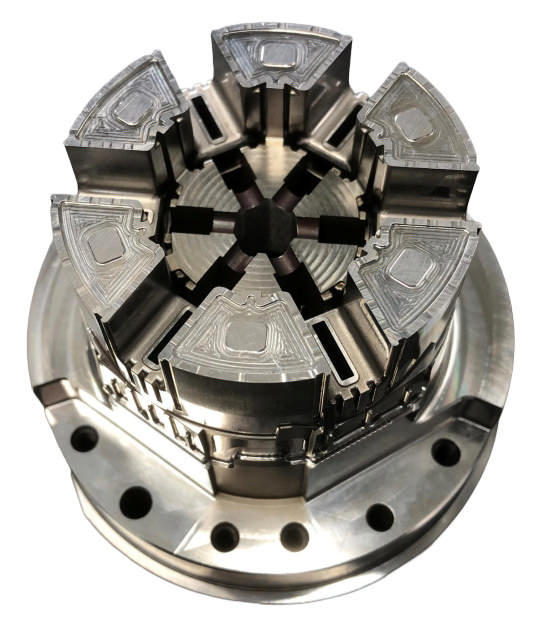

Collapsing core for injection moulding tool

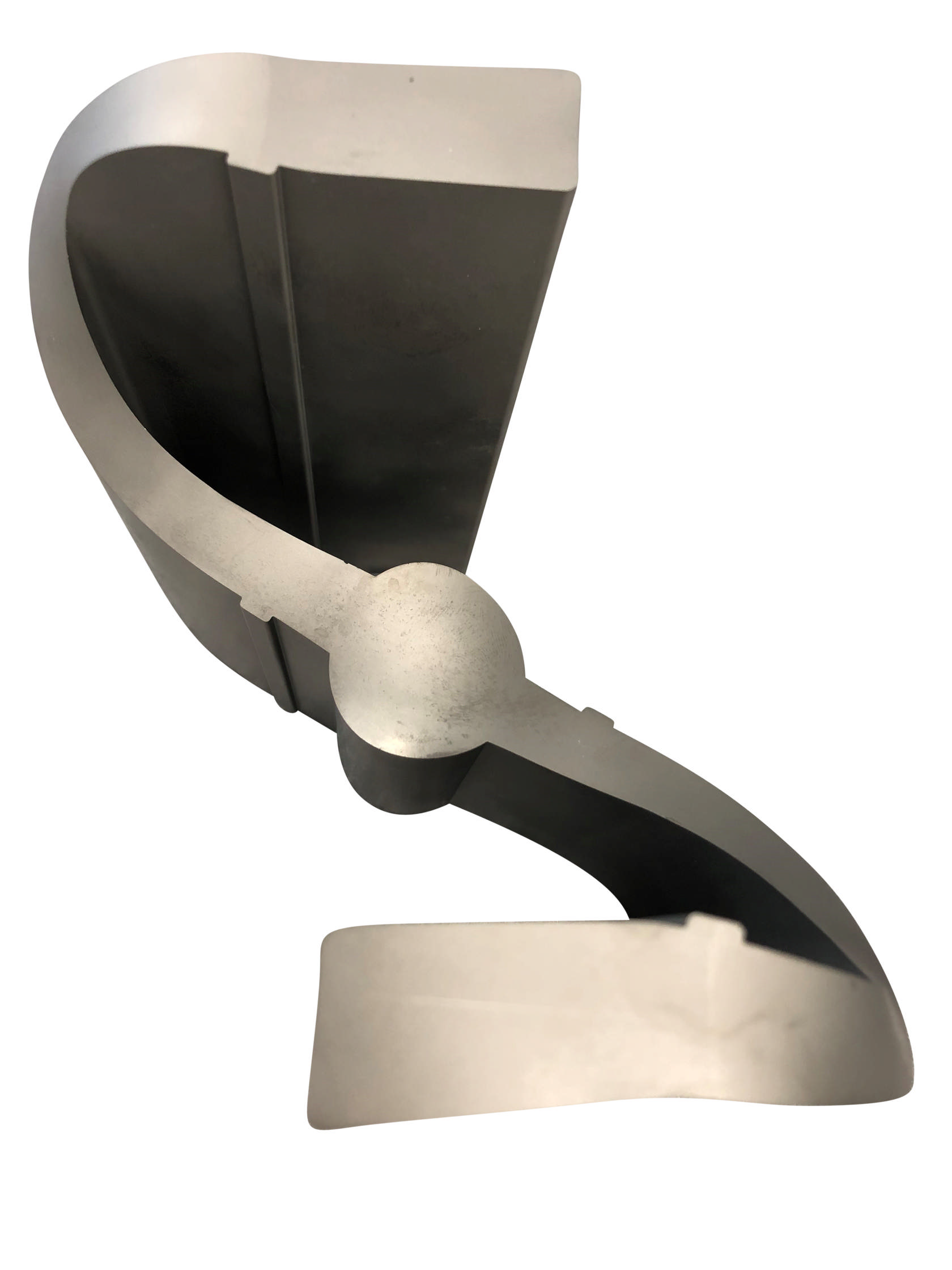

Punch for bending and cutting tools

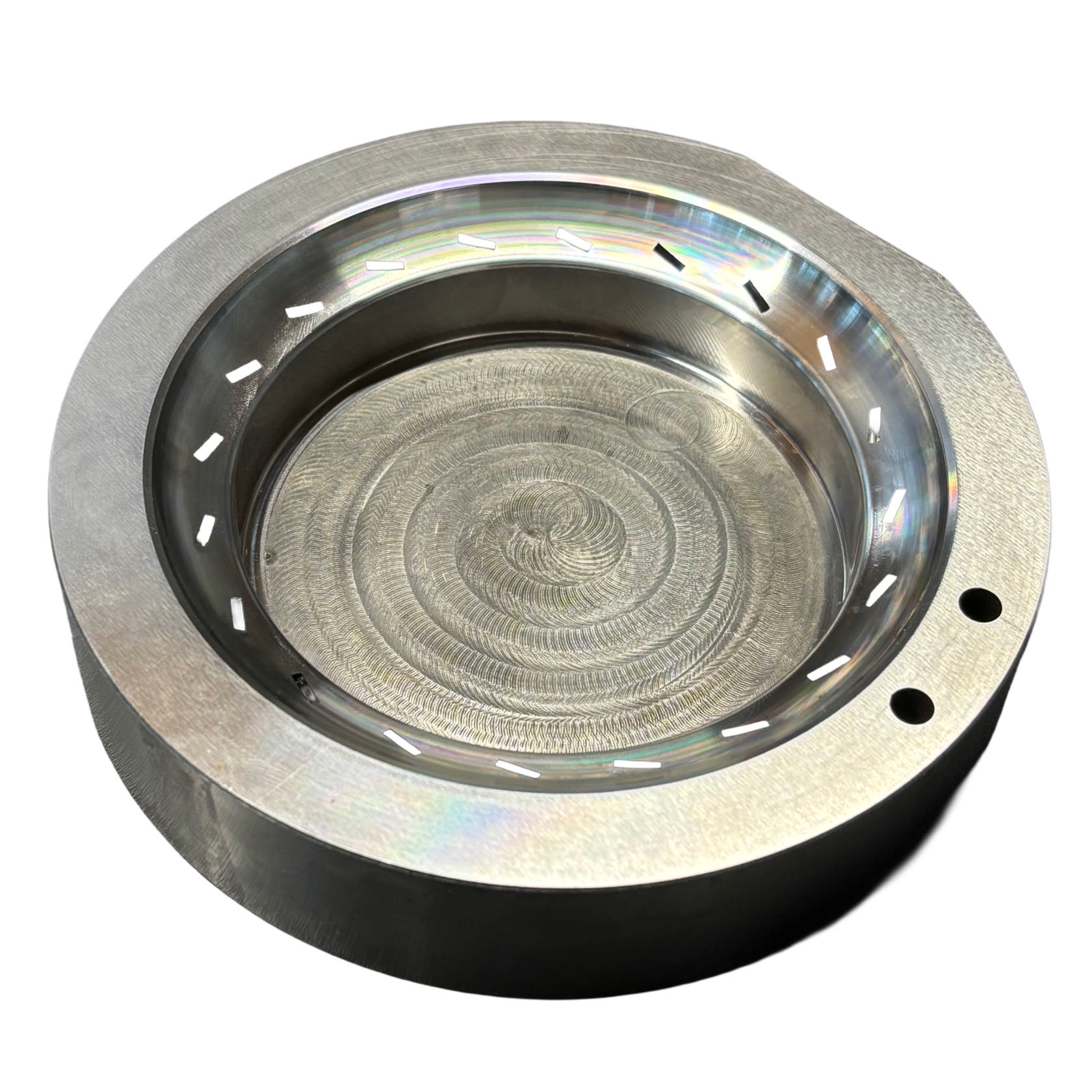

Ejector punch for deep-drawing

Roller mandrel

Whether it involves new production, repair, or optimisation of tool components, we provide guidance on the right tool materials, surface treatments, and the most efficient manufacturing processes.

Learn more about our machine park, measuring facilities, and the materials we typically work with.

Hardening and Surface Coating

Extend service life with the right finish

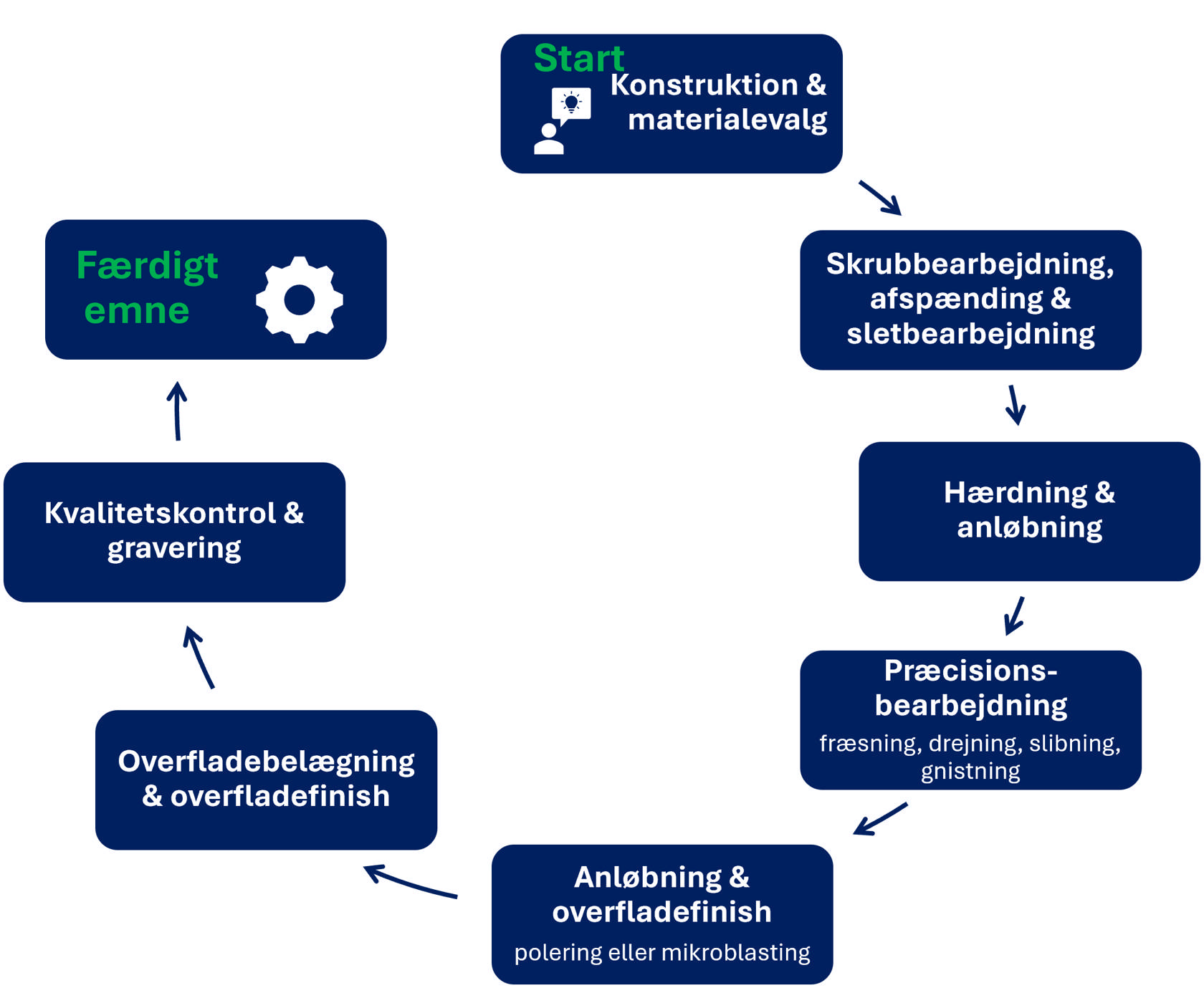

At Unika Denmark, we work purposefully to extend the service life of the machine components we produce. We know that the choice of steel and surface treatment plays a crucial role. That is why we collaborate with external partners on the development and optimisation of steel grades, hardening, and surface coatings.

Through this collaboration, we gain access to the latest knowledge in material technology, hardening methods, and wear resistance, which we actively apply in advising our customers. The result is machine components with significantly improved service life – benefiting both operational reliability and production economy.

Several techniques can help extend service life:

Heat treatment: Hardening, tempering, and nitriding to increase hardness, wear resistance, and toughness.

Precision machining with high-quality equipment: Including hydrostatic machines to reduce vibrations and backlash during processing.

Surface preparation, texturing, and design optimisation: Designing fillets, reducing friction, avoiding micro-cracks, exposing carbides, and creating microstructured surfaces for lubricant films.

Coatings: For wear resistance, heat resistance, and reduced friction.

Contact us if you need expert advice

Whether you are working on a new design, a renovation, or an optimisation project, we provide technical guidance and material selection based on proven knowledge and practical experience.