Durable machine parts

Durable Machine Parts

We provide extended service life for wear parts for industry and solutions for demanding production environments.

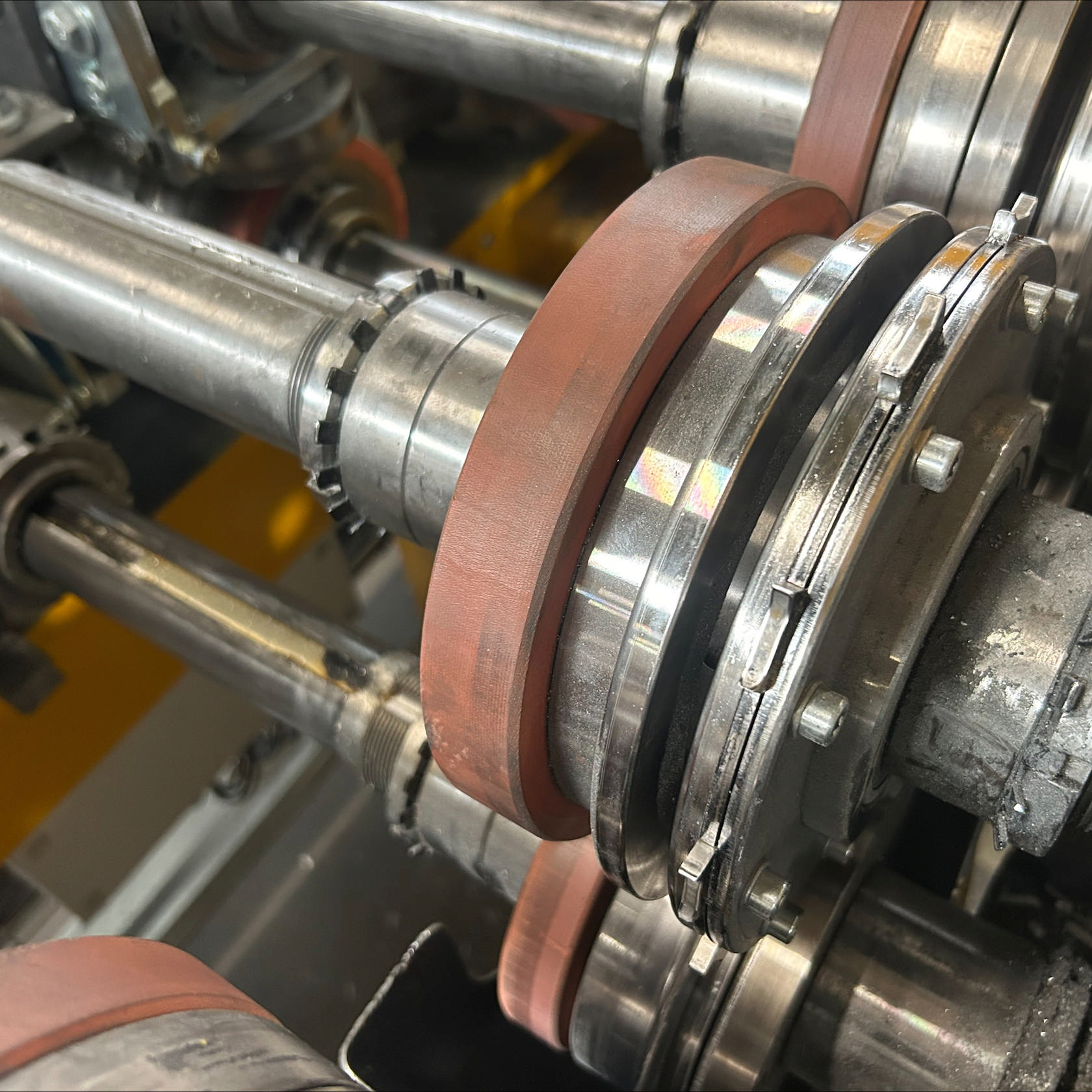

In many manufacturing companies, wear parts are exposed to high loads, continuous operation, and demanding environments. At Unika Denmark, we help the manufacturing industry extend the service life of critical components, minimising maintenance and optimising operations.

We collaborate with companies in, among others, the following industries:

- Food industry – we are FKM certified

- Construction industry

- Metal industry

- Packaging industry

In these industries, wear, corrosion, and repeated stress place high demands on materials and design.

We have the experience to manufacture your machine components

If you need machine components that are exposed to heavy wear, used in environments requiring frequent cleaning, or that demand high precision, we can help.

Welding fixture

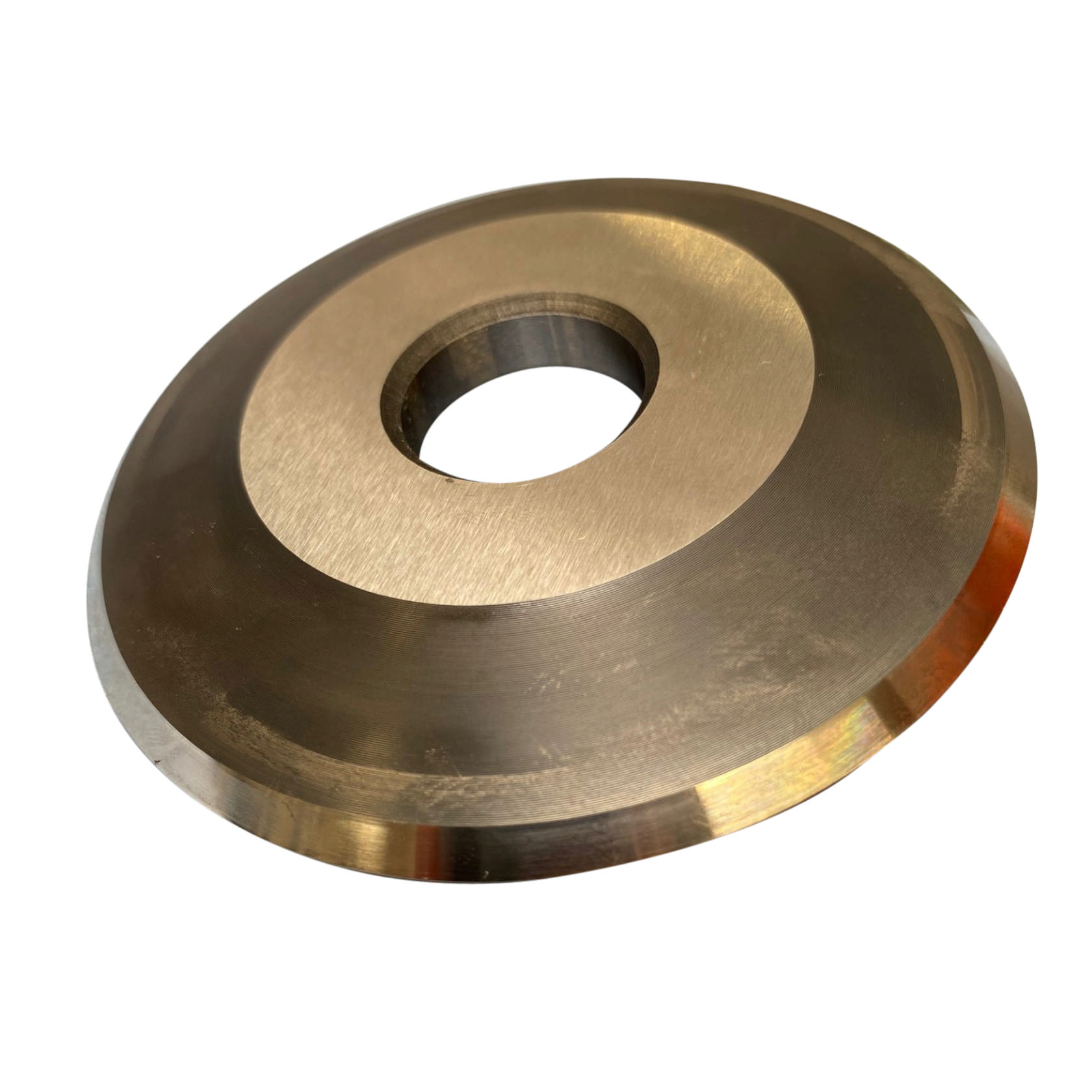

Coated cutting knife

Custom machine part

Precision coupling

Tool guide

By combining our extensive experience in precision machining with expertise in steel and surface treatments, we can offer solutions that:

- Extend component service life

- Reduce the risk of breakdowns

- Lengthen maintenance intervals

- Improve the overall cost-efficiency of production

We provide guidance on the right materials, surface treatments, and the most efficient manufacturing processes.

If you have wear parts that require frequent replacement, let us help make them more durable.

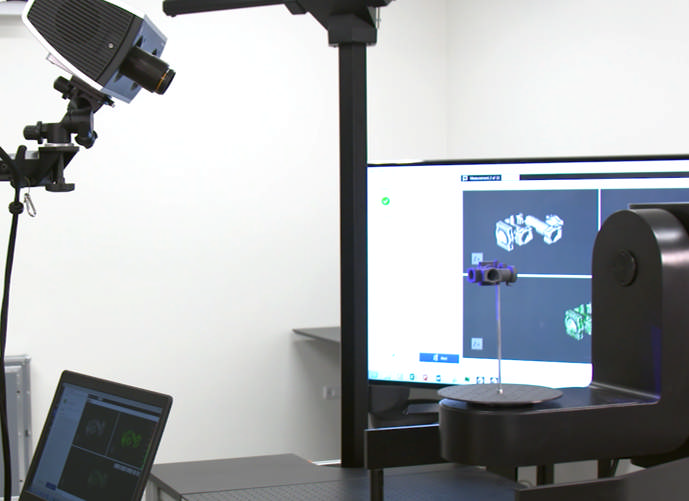

Reverse Engineering

If you lack drawings for specific tool components or similar parts, we can perform reverse engineering based on 3D scanning with an accuracy of approximately 0.02 mm.

Learn more about our machine park, measuring facilities, and the materials we typically work with.

Hardening and Surface Coating

Extend service life with the right finish

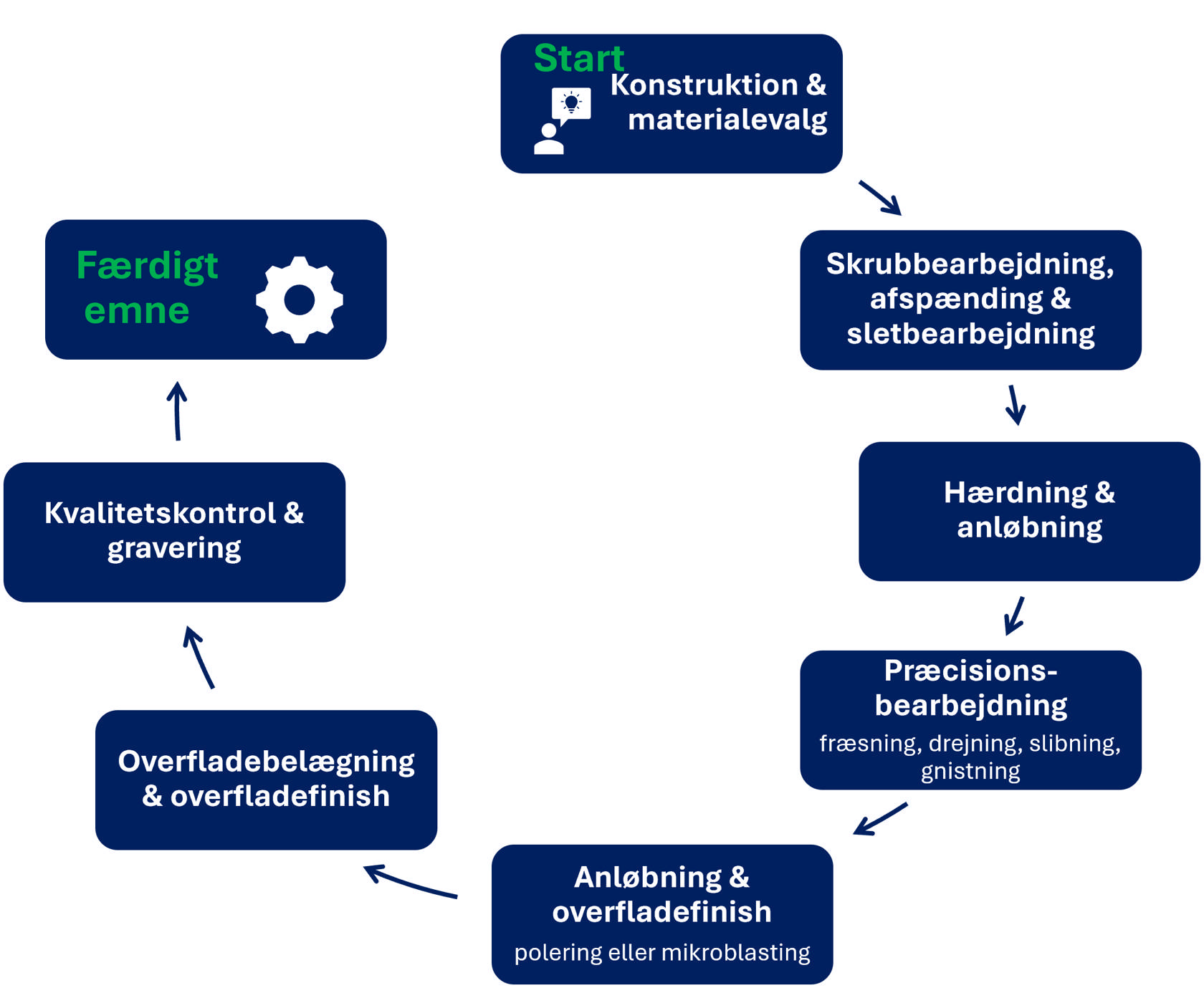

At Unika Denmark, we work purposefully to extend the service life of the machine components we produce. We know that the choice of steel and surface treatment plays a crucial role. That is why we collaborate with external partners on the development and optimisation of steel grades, hardening, and surface coatings.

Through this collaboration, we gain access to the latest knowledge in material technology, hardening methods, and wear resistance, which we actively apply in advising our customers. The result is machine components with significantly improved service life – benefiting both operational reliability and production economy.

Contact us if you need expert advice

Whether you are working on a new design, a renovation, or an optimisation project, we provide technical guidance and material selection based on proven knowledge and practical experience.

Several techniques can help extend service life:

Heat treatment: Hardening, tempering, and nitriding to increase hardness, wear resistance, and toughness.

Precision machining with high-quality equipment: Including hydrostatic machines to reduce vibrations and backlash during processing.

Surface preparation, texturing, and design optimisation: Designing fillets, reducing friction, avoiding micro-cracks, exposing carbides, and creating microstructured surfaces for lubricant films.

Coatings: For wear resistance, heat resistance, and reduced friction.