Injection Moulding at unika

Injection Moulding At unika

At Unika, we offer injection moulding both with and without our own tools. As a customer, you can choose to use injection moulding tools that are:

- Manufactured at Unika

- Sourced from a low-cost manufacturer

- Existing tools relocated to Unika

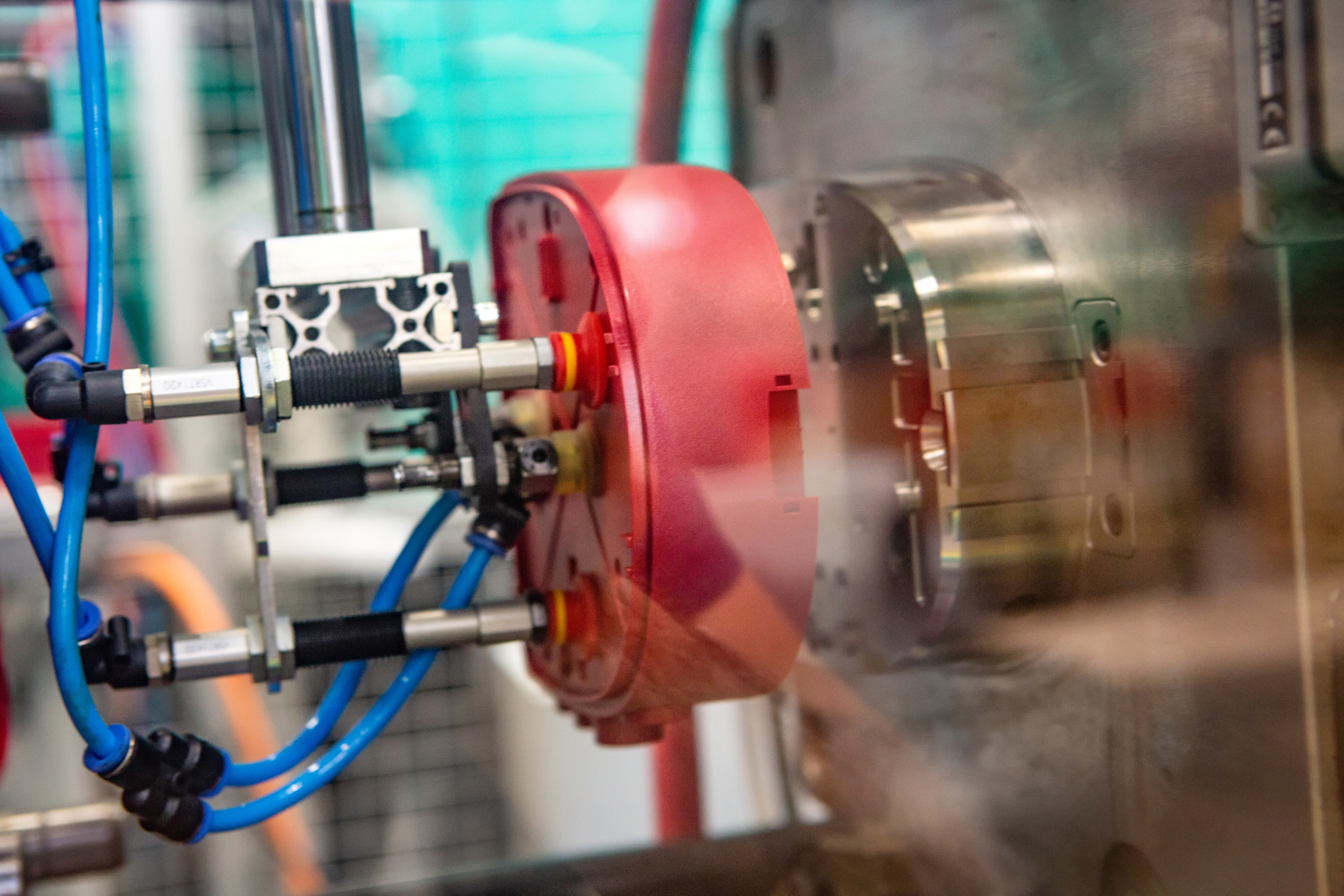

No matter the tool, we have the experience and a highly automated production setup with 39 injection moulding machines operating across three shifts. This enables us to deliver the required components quickly and efficiently.

We produce plastic components in both small and large series, ranging in weight from 0.1 grams to 12 kilograms – from tiny precision parts to large, robust components.

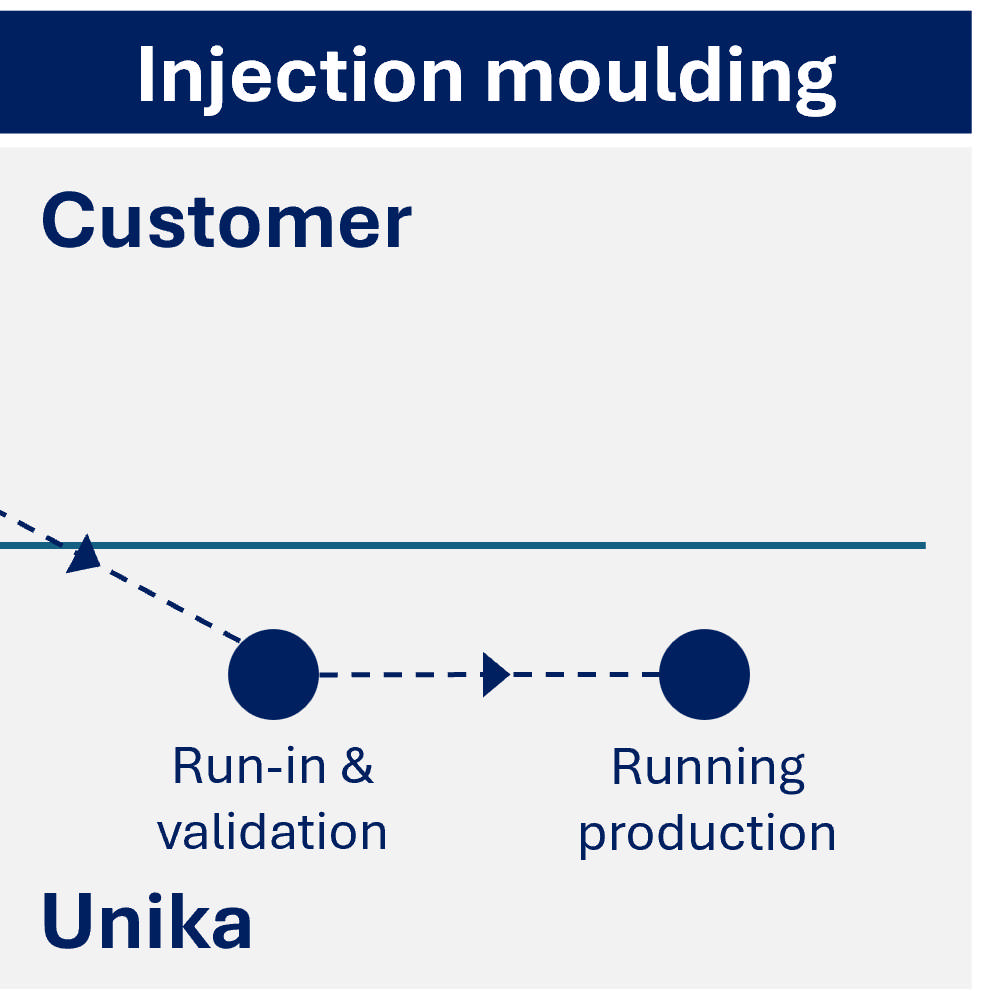

Fast commissioning and production start

We have all the in-house expertise required to quickly and efficiently commission and start production of a new injection-moulded component.

In case of issues with an injection moulding tool, we can respond very quickly, as experts from our own tool design and manufacturing department can be on-site within minutes to help resolve any problems.

Documentation and a quality package supporting production start-up are, of course, included. This may consist of complete PPAP documentation or selected elements, depending on the process requirements.

decorating, post-assembly, or storage

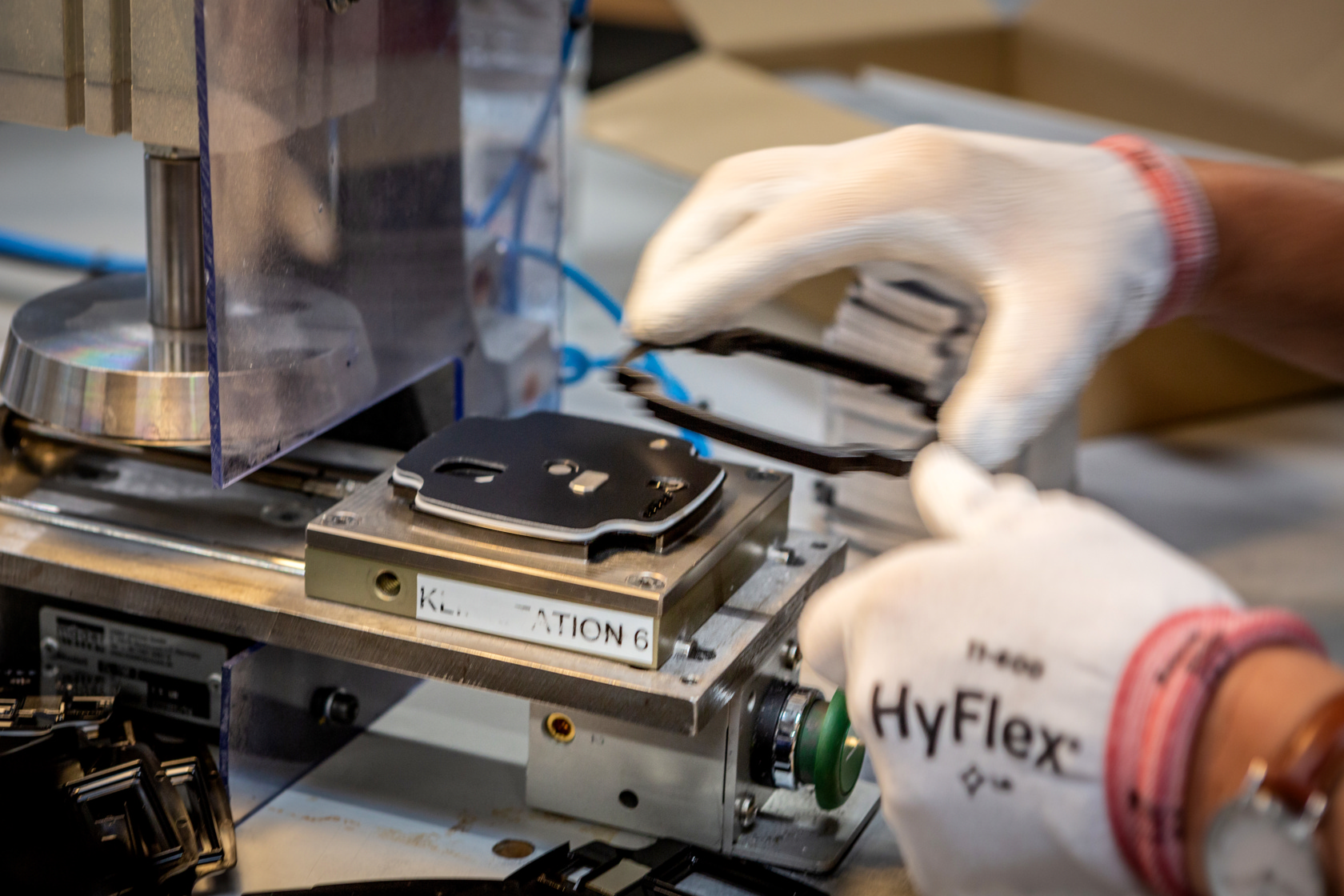

Many injection-moulded components are packed directly at the injection moulding machine by a robot and are ready to be shipped straight to your production line.

If further processing or a logistics setup is required, we can provide that as well. This may include:

- Pad printing, application of labels, or engraving

- Assembly of wires, bushings, threaded inserts, and similar components

- Packaging in consumer-ready packaging with instructions, so the components are ready to be shipped directly to distributors and customers.

- Flexible storage solutions available as needed

Pad printing

Secondary assembly

Storage solution

QUICK Repair = Minimal Downtime

When it comes to maintaining your moulding tool, our in-house toolmakers ensure it stays in optimal condition. This allows it to perform at its best throughout its entire service life, with any issues being addressed quickly.

Our experienced toolmakers and versatile machinery enable us to handle a wide range of tooling challenges quickly and efficiently:

- We are experts in injection moulding and fully understand operational challenges

- We have all repair processes handled in-house

- Quick response, so downtime and delays are minimized