injection Moulding machines

Flexible Machine Park for Injection Molding

Efficient, Flexible, and Energy-Conscious

With 39 injection moulding machines operating around the clock, we handle everything from simple components to complex multi-component (2K) solutions. Our machine park covers a wide range of machines.

- Electric machines: Fast, energy-efficient, and extremely precise – ideal for thin-walled parts and tight tolerances

- Hydraulic machines: Powerful and robust, suitable for larger parts and long production cycles

- Vertical machines: Enable overmolding of metal inserts and special components

- 2K machines: For parts made from multiple materials or colors in a single molding process

- From 0.01 g to 12 kg per shot

- Clamping forces: From 40 to 1,300 tons

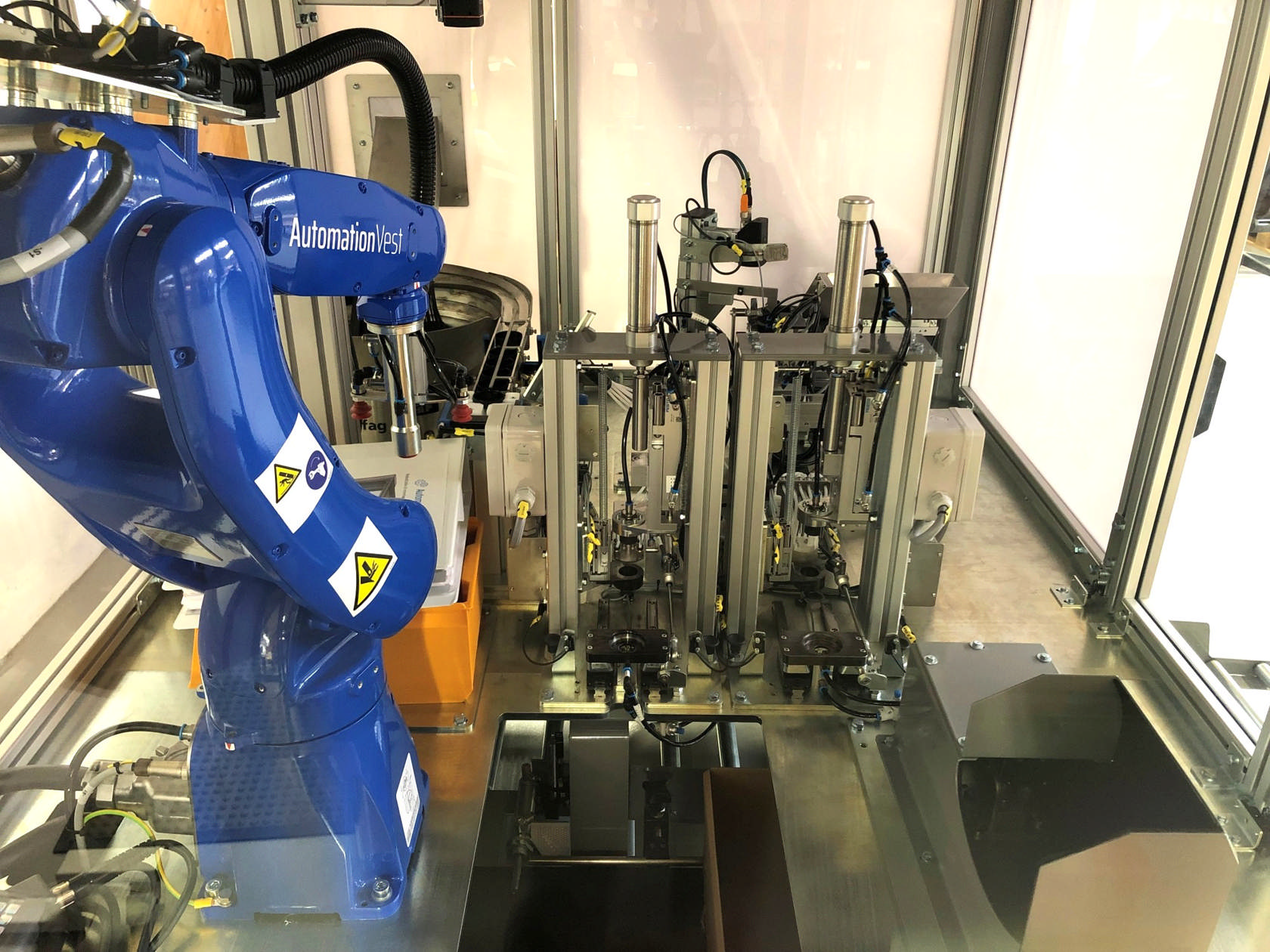

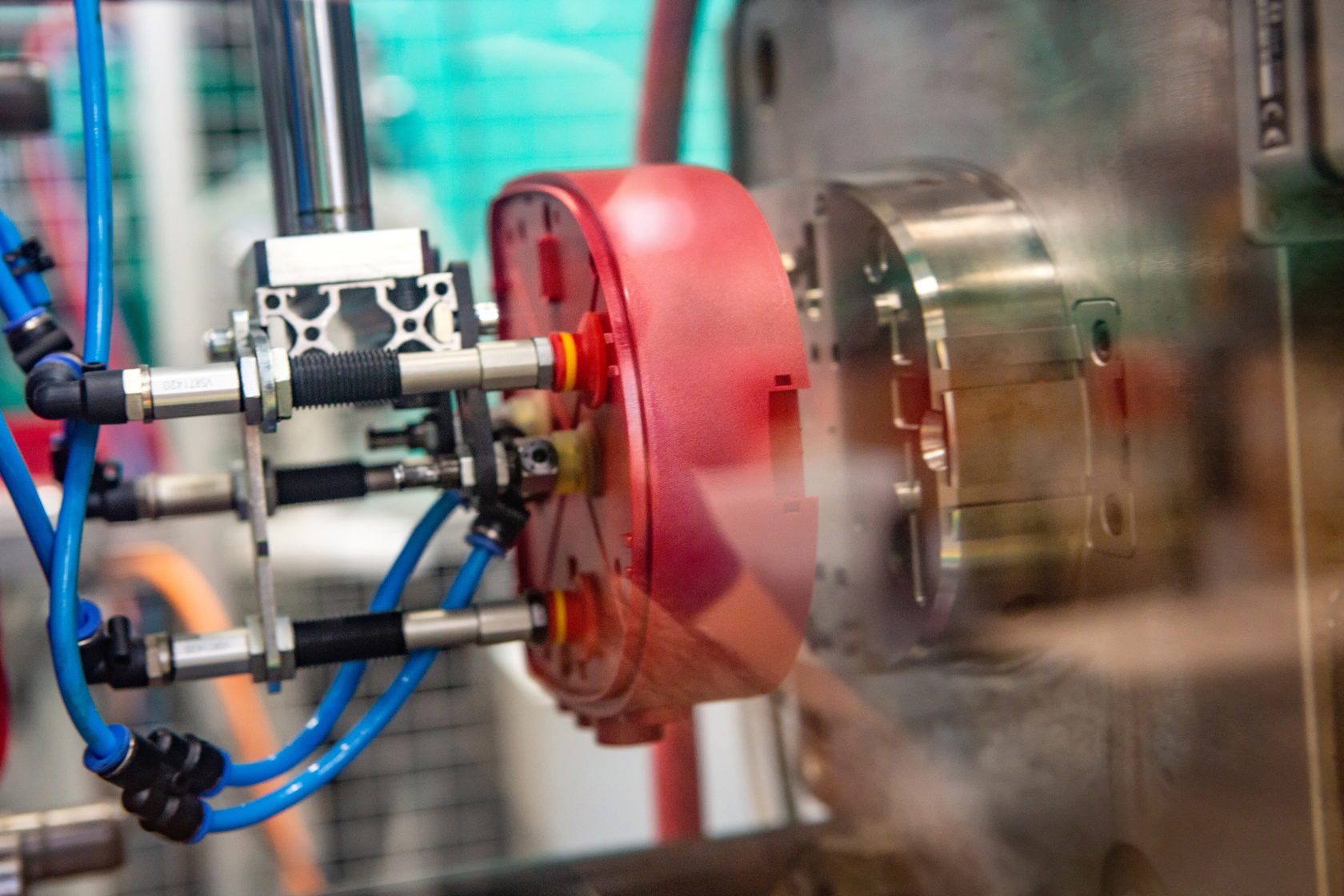

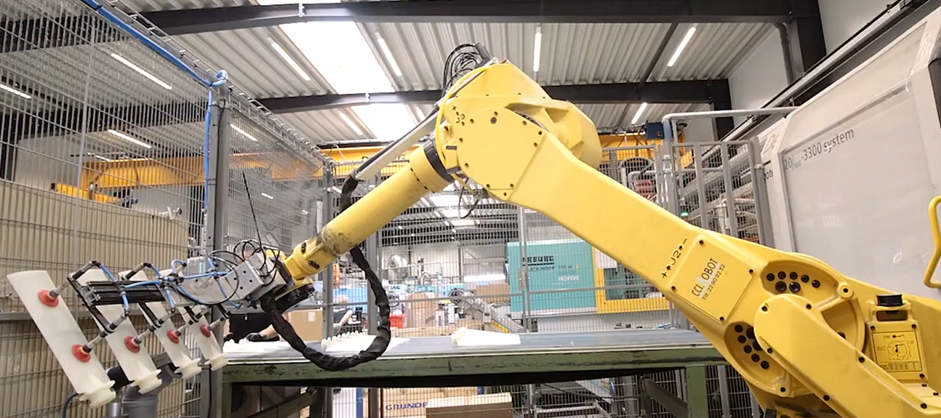

Automation with Robots

Provides efficient, consistent, and reliable production

To ensure high operational reliability and consistent quality in production, many of our injection moulding machines are equipped with robotic automation.

- Provides gentler handling of parts

- Several robotic systems feature integrated vision for part inspection

Three-axis (traverse) robots

- Integrated linear robots that automatically remove parts from the mould and can stack, insert, or transfer components.

- They provide shorter cycle times, high repeatability, and efficient logistics directly at the machine.

Cobot solutions (collaborative robots)

- Flexible cobots handle tasks such as part loading, post-processing, or packaging.

- They can operate safely alongside operators without safety barriers — ideal for small series or varying parts.

- Cobots contribute to smooth and safe workflows while reducing the manual burden on employees performing routine tasks.

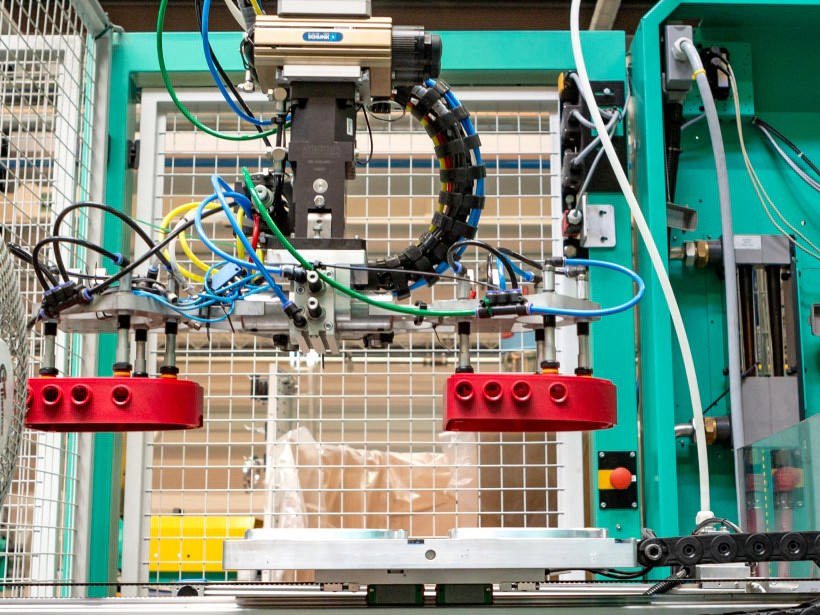

Automated assembly cells for post-assembly

For parts requiring extensive post-assembly, we have highly automated, customer-specific assembly cells to ensure reliable operation and consistent quality in production.