Injection Moulding tools from abroad

Injection Moulding tools from abroad

Unika is responsible for quality assurance

We collaborate with selected tool suppliers in Europe and Asia. This allows us to offer sourcing and project management of tools for customers who want a competitive price without compromising on quality.

We handle:

- Technical specifications and design review

- Close quality control and inspection

- Inspection, testing, and fine-tuning in Denmark

- Support and maintenance after delivery

With Unika as the link, you gain confidence and technical insight throughout the entire project – even when the tool is manufactured outside of Denmark.

Importing tools from abroad is a good idea when...

- Limited budget – when a smaller investment is desired

- Simple parts with a locked design – the simpler the design, the lower the risk of misunderstandings along the way

- Less extensive documentation requirements for part and tool – since preparing a comprehensive PPAP documentation package can be demanding

- Low documentation requirements for part and tool – for example, when it’s not possible to obtain a complete PPAP documentation package from the foreign supplier

- Plenty of time in the project – the project must not be time-critical, as it takes time to receive test samples and to have the finished tool shipped

Typical challenges with tools produced abroad

- Design and IP protection – if the product’s function must remain confidential, foreign production is generally less secure than in Denmark.

- Design changes – late-stage changes are more complicated and time-consuming abroad than with local production.

- Longer project duration – additional time is usually required for shipping sample parts for approval and transporting the finished tool.

- Tool documentation – we sometimes experience discrepancies between the actual tool and the provided drawings/documentation.

- Correction delays – if issues arise once the tool has arrived in Denmark, fixing them through the foreign supplier can take considerable time.

project Process

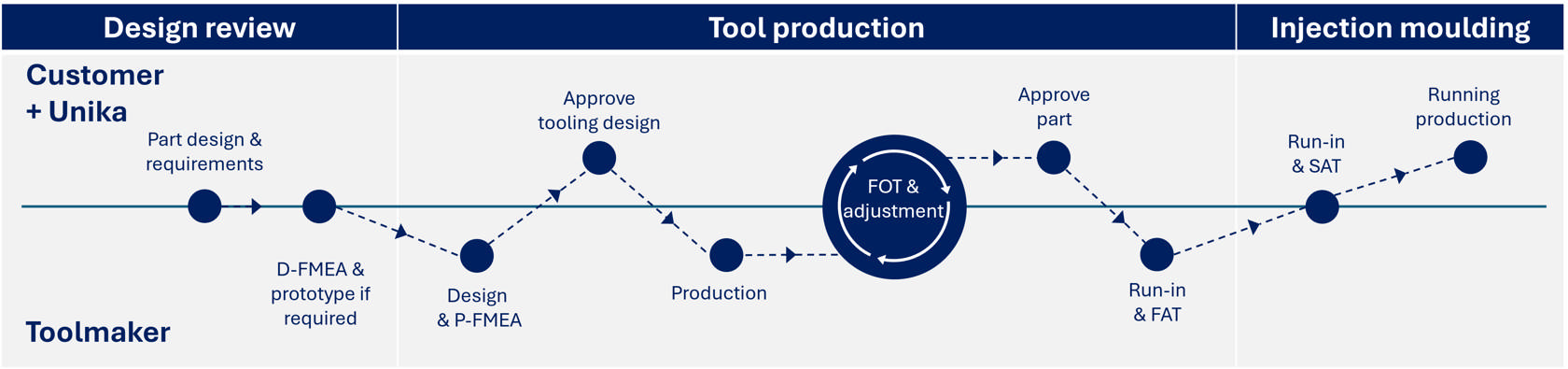

In the process, we go through the same steps as when the mould is produced at Unika in Denmark, where:

- Our experienced tool designers review, challenge, and approve the supplier’s proposal.

- FOT parts – and any subsequent samples from the test moulding – are sent to Denmark for approval by both the customer and Unika.

- Once the parts and the mould are finally approved, the mould is shipped to Denmark, where it can be tested at Unika or directly at your site.

It is possible to purchase a tooling warranty from Unika as an extra layer of security when having your mould manufactured abroad.