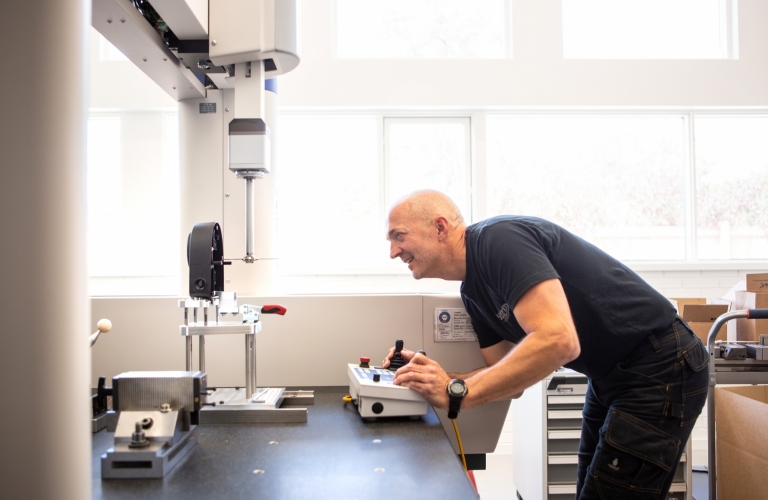

Frank is specialist in Unika's third measuring machine, a new surface scanner from Zeiss.

Colour mapping is used to compare the scanned subject with a 3D drawing model or an approved Master-subject. The differences between these subjects can be expressed in colour differences on the computer screen. With this method, we can get a very clear picture of which tolerances are met and where we need to have the customer in dialogue about possible adjustments.

If there is not already a drawing on the subject, we can use the data from our new Zeiss surface scanner to reverse engineering.

This means that our designer can make both a drawing and a 3D model of the item based on the measured data. In this way, technical files can be created based on any subject, even if it is just a sawn tree model or made of a model wax. We can also help our customers to document older topics where, for example, drawing material is not available.

Dansk

Dansk Engelsk

Engelsk