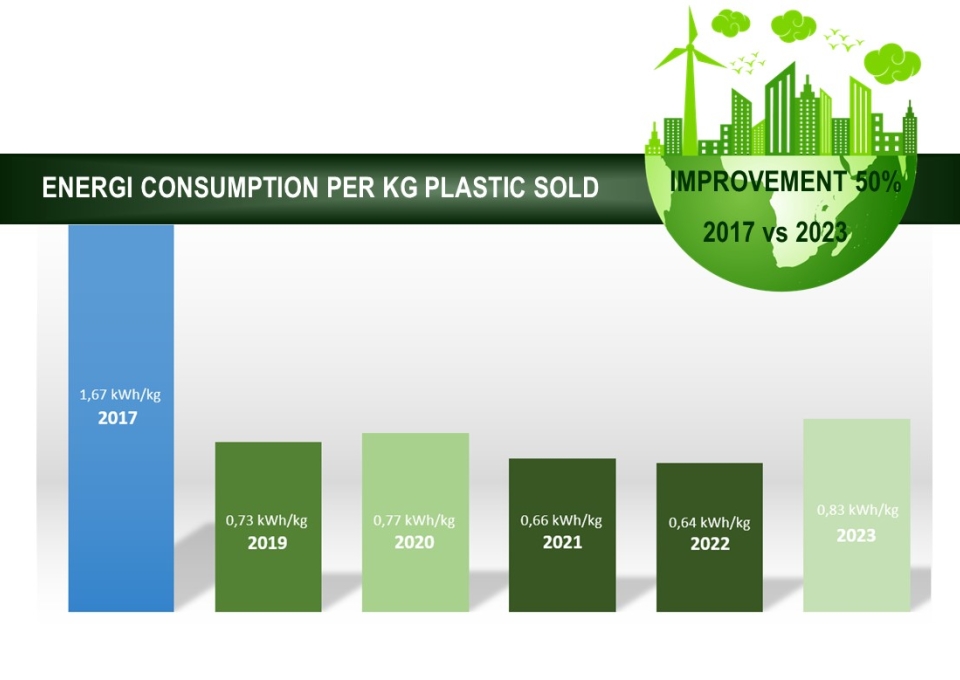

The year 2017 started with a plan for how Unika could reduce energy consumption in the production. An employee got the brilliant idea that we could reuse the large amount of surplus heat that disappeared into the air every minute, hour, day and week. At the same time we considered the following energy improvements in the project:

- Avoid the halls becoming too hot in relation to the required working temperatures

- Achieve better control of the cooling water temperature for molds and injection molding machines

- Compliance of the UN's World Goal number 12, Responsible consumption and production

- Get rid of oil firing

- Deliver surplus heat to Ans CHP plant

The wish was to utilize the surplus heat from the production machines in connection with heating and melting of plastics and at the same time think green conversion.

A collaboration with Solar Cooling was initiated and calculations of the size of the plant and how the utilization could be distributed were prepared.

The idea became reality during 2018.

The green advantage

The surplus heat is passed on to Ans CHP plant and the green advantage is that the excess heat is CO2 neutral for Ans District heating. In addition, production wastage at Unika is reduced because of a better control of the temperature of the cooling water in the manufacturing of molds and in the plastic injection molding itself.

Dansk

Dansk Engelsk

Engelsk